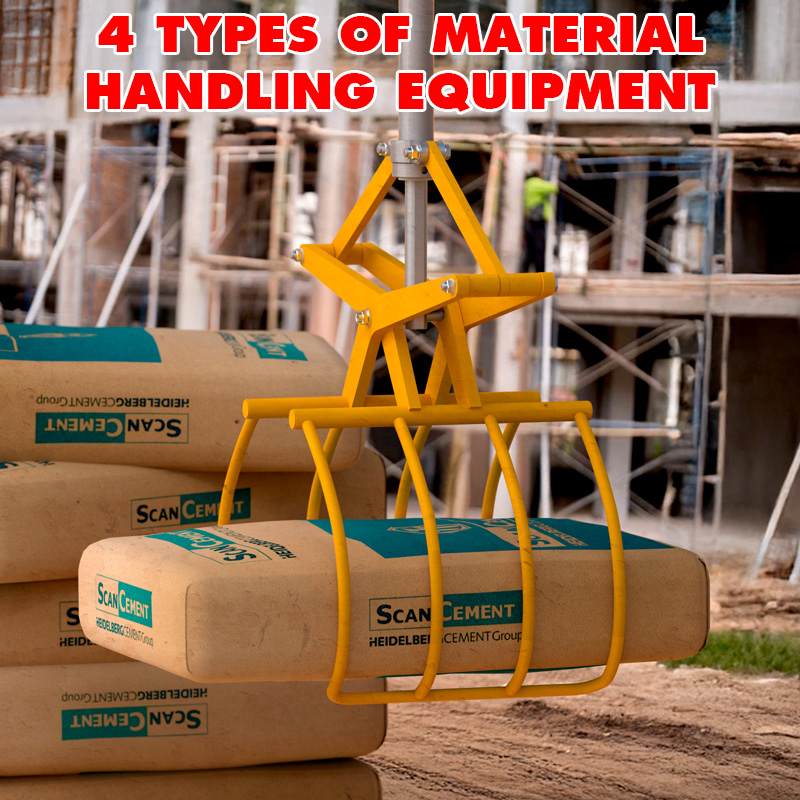

4 Types of Material Handling Equipment and Their Uses

Material handling equipment plays a pivotal role in manufacturing, warehousing, construction, and logistics industries.

By improving operational efficiency, reducing manual labor, and minimizing downtime, businesses can optimize their workflows significantly. In this article, we will explore the four main types of material handling equipment, their uses, and how to choose the right type for your needs.

Explore more about Material handling Equipment.

Overview of Material Handling Equipment Categories

The material handling industry is growing rapidly, with a projected market value expected to reach $288.4 billion by 2028 (Grand View Research). This growth highlights the increasing need for advanced systems that facilitate safe, efficient, and automated material management.

| Category | Common Uses | Typical Equipment Examples |

|---|---|---|

| Storage and Handling Equipment | Storage, organization, and inventory | Shelves, racks, mezzanines |

| Industrial Trucks and Machines | Material transportation | Forklifts, pallet jacks, order pickers |

| Bulk Material Handling Equipment | Moving large quantities of bulk materials | Conveyors, hoppers, dump trucks |

| Engineered Systems | Automated storage and retrieval | Warehouse robots, sortation systems |

Storage and Handling Equipment

Storage and handling equipment are fundamental tools designed to hold materials between manufacturing processes. They help maximize vertical and floor space.

Common Tools:

-

Bins and Drawers: Ideal for small to medium items.

-

Mezzanines: Add an extra floor level to maximize warehouse space.

-

Pallets and Pallet Stacking Frames: Allow easy transportation of bulk goods.

-

Storage Racks: Help organize inventory and maximize vertical space.

Learn about practical examples of material handling.

Industrial Trucks and Machines

Industrial trucks assist in moving materials over variable paths without a fixed route. They can be manually operated or powered vehicles.

Popular Industrial Trucks:

-

Forklifts: Load capacities up to 25,000 pounds. See more about our Vacuum Lifter that complements lifting tasks.

-

Order Pickers: Help retrieve items from higher shelves.

-

Pallet Jacks: Used for moving palletized loads across short distances.

-

Side Loaders: Ideal for narrow aisle operations.

-

Walkie Stackers: Provide easy pallet stacking in tight spaces.

Related Tools:

-

Ratchet tie down: Essential for securing loads on trucks.

-

Ratchet tie down straps: Reliable tools for load management.

Bulk Material Handling Equipment

Bulk handling systems are designed for the movement, storage, and control of loose materials like grain, ore, or coal.

Key Bulk Handling Equipment:

-

Conveyors: Streamline movement within production facilities.

-

Hoppers: Transport agricultural products efficiently.

-

Dump Trucks: Transport construction materials such as dirt and debris.

-

Bucket Elevators: Move flowable bulk materials vertically.

-

Bulk-Handling Cranes: Specialized cranes for handling large volumes.

Notable Equipment:

-

Stackers and Reclaimers: Essential for stockpile management.

-

Silos: Provide vertical bulk storage for industries like farming and mining.

Engineered Systems

Engineered systems are automated solutions tailored for large warehouses and manufacturing setups.

Examples:

-

Automated Storage and Retrieval Systems (AR/RS): Robotically place and retrieve inventory.

-

Automated Guided Vehicles (AGVs): Follow wires or magnetic strips for navigation.

-

Autonomous Mobile Robots (AMRs): Adapt and respond dynamically to surroundings.

-

Palletizers: Automatically stack items on pallets.

-

Sortation Systems: Direct products to correct destinations.

-

Warehouse Robots: Perform repetitive tasks efficiently.

Learn more about gantry cranes for large lifting operations.

How to Choose the Right Material Handling Equipment

Factors to Consider:

-

Function and Space Optimization: Evaluate warehouse layout and operational flow.

-

Type of Materials: Consider size, weight, and fragility of materials.

-

Manual Labor vs Automation: Balance upfront costs with long-term efficiency.

-

Industry-Specific Requirements: Construction may require heavier equipment like Slab Lifters or jib cranes (More about Jib Cranes).

-

Cost Efficiency: Ensure the investment aligns with ROI projections.

According to Statista, the material handling industry in the U.S. alone is expected to witness a CAGR of 6.2% from 2023 to 2028, indicating a surge in demand for lifting equipment like vacuum lifters, gantry cranes, and ratchet tie down solutions.

Final Thoughts

Choosing the right material handling equipment is crucial for maximizing productivity, safety, and operational efficiency. From basic storage bins to sophisticated warehouse robotics, each type serves a vital role across industries.

For comprehensive material handling solutions including forklifts, vacuum lifters, slab lifters, gantry cranes, and ratchet tie down straps, trust Aardwolf for reliable, high-quality products.

Ready to optimize your operations? Explore Material handling Equipment and discover the right solutions today.

Follow us on: