Lifting Boxes | The Key to Streamlined Material Handling

In today’s fast-paced industrial environment, lifting boxes efficiently is essential for optimizing workflow and maintaining a safe work environment. Whether you’re in manufacturing, warehousing, or logistics, having the right material handling strategy is crucial. From selecting the appropriate material handling equipment to ensuring safe and ergonomic practices, lifting boxes effectively can help businesses reduce operational costs, prevent workplace injuries, and boost overall productivity.

The Role of Lifting Equipment in the Material Handling Industry

Why Proper Handling Material Matters

The material handling industry relies on specialized lifting equipment to move goods quickly and safely. Improper handling material techniques can lead to damaged products, employee injuries, and increased downtime. By investing in reliable material-handling equipment, companies can:

-

Enhance Safety: Reduce the risk of strains, sprains, and other injuries associated with manual lifting.

-

Improve Efficiency: Streamline operations by allowing workers to move larger quantities of boxes in less time.

-

Boost Productivity: With the right tools, employees can focus on higher-value tasks rather than struggling with repetitive lifting.

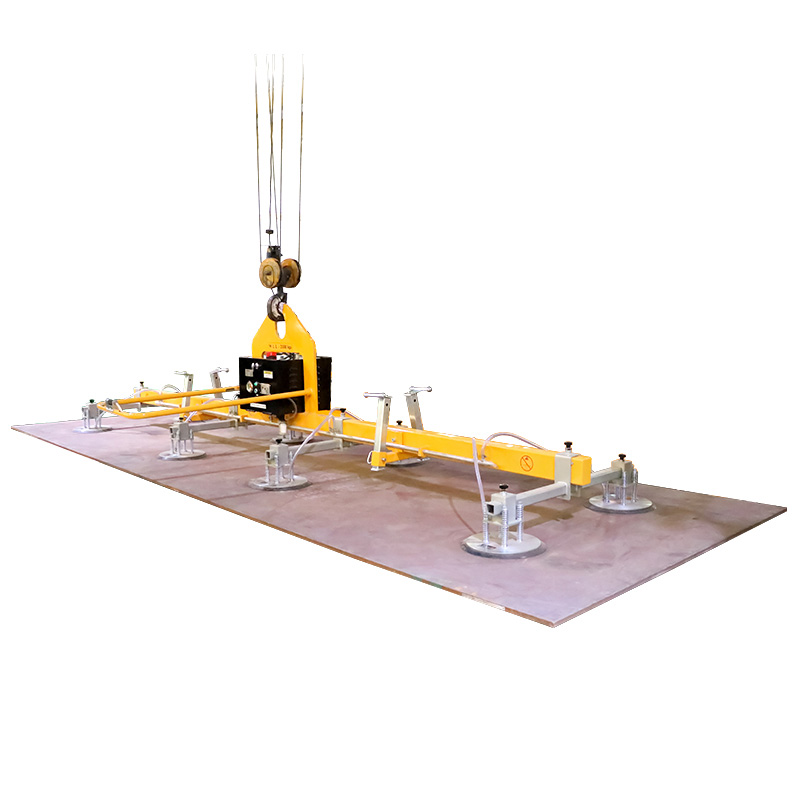

How Material Handling Companies Innovate

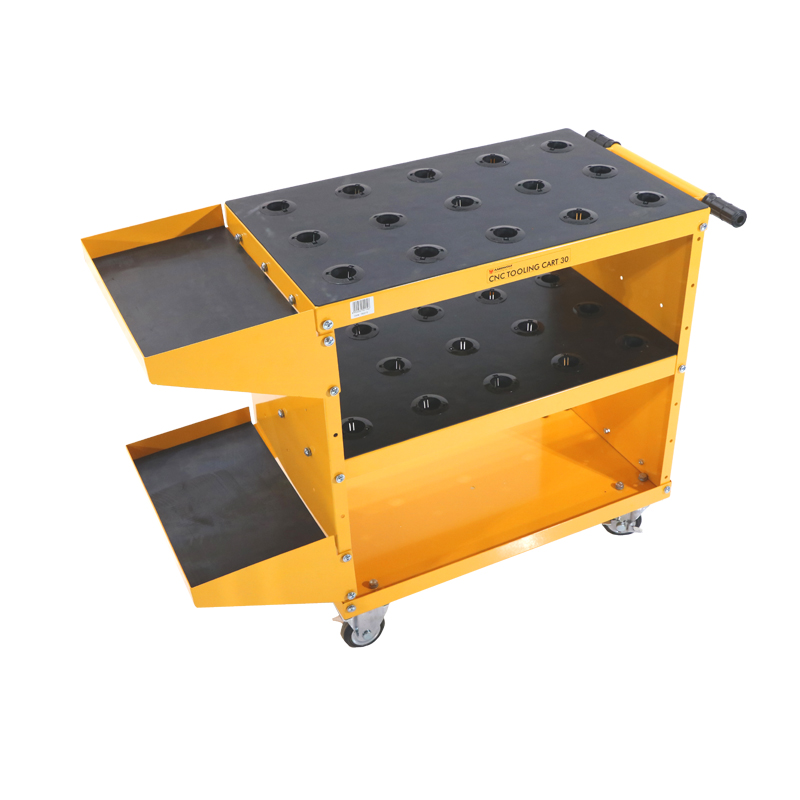

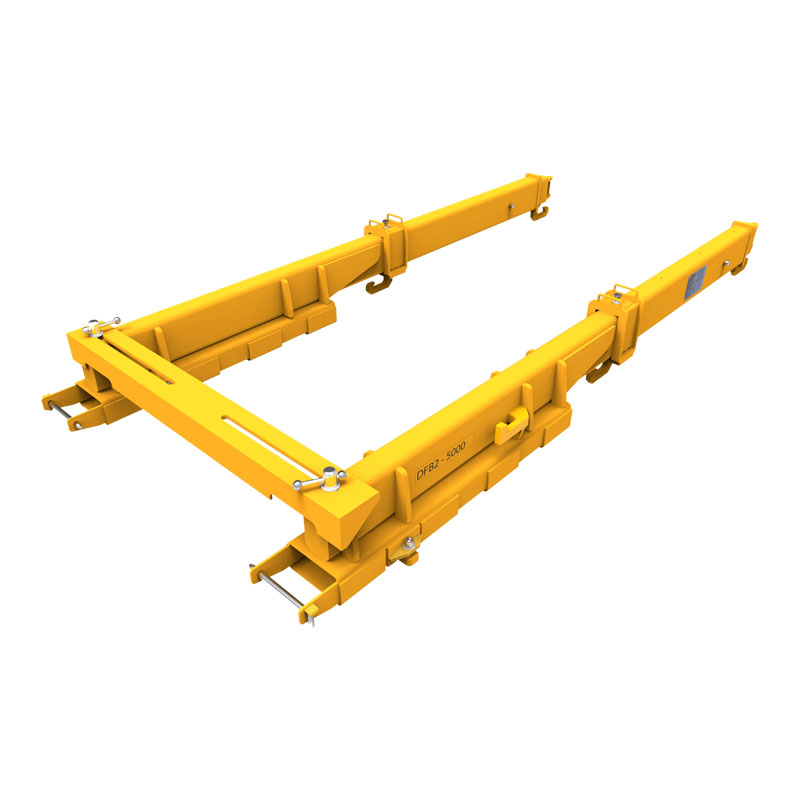

Many material handling companies are developing innovative solutions to meet the growing demands of modern businesses. These companies focus on creating equipment that is:

-

Ergonomic: Designed to reduce physical strain on workers.

-

Durable: Engineered to withstand the rigors of daily industrial use.

-

Adaptable: Capable of handling various box sizes, shapes, and weights.

Whether you’re looking for a lifting box system or a more advanced racking system, partnering with the right material handling provider ensures you have the necessary tools to keep your operations running smoothly.

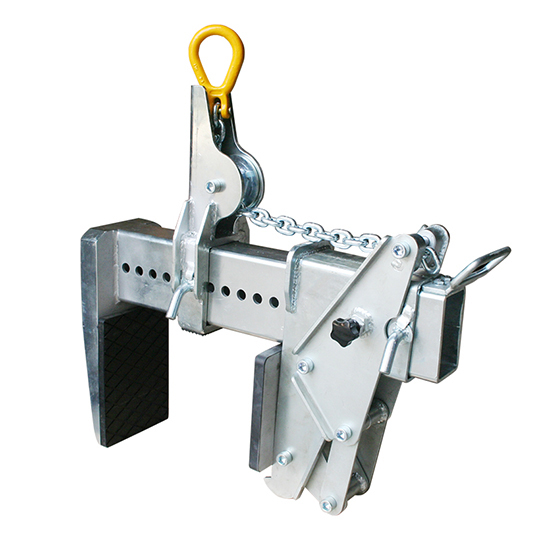

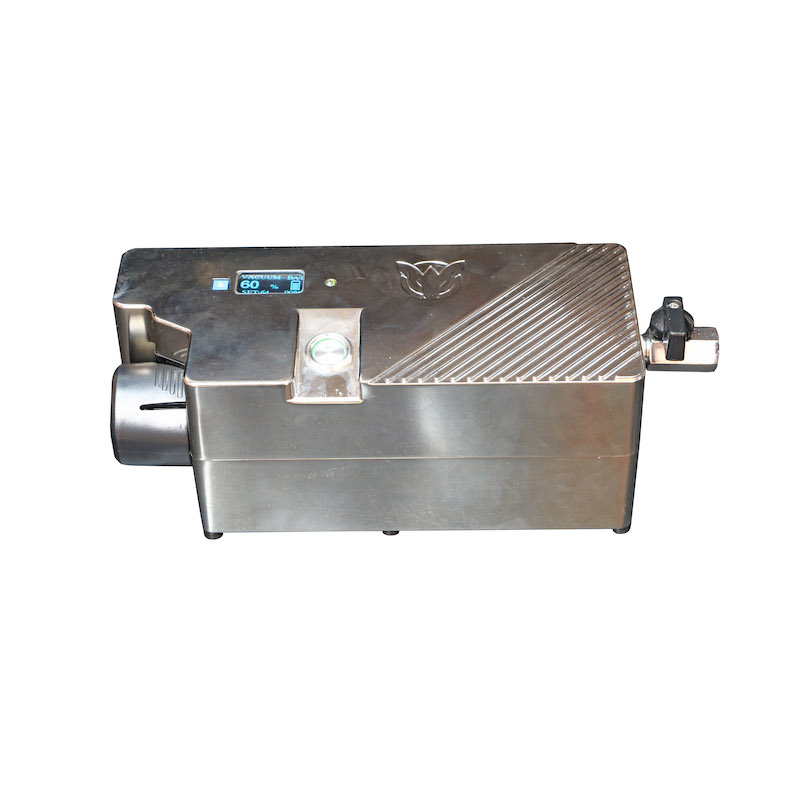

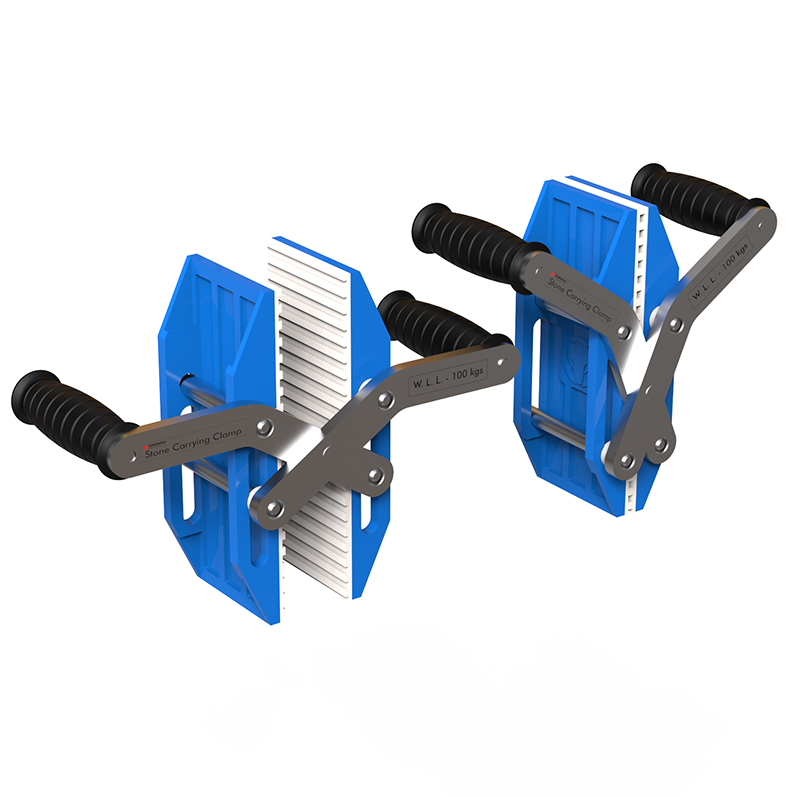

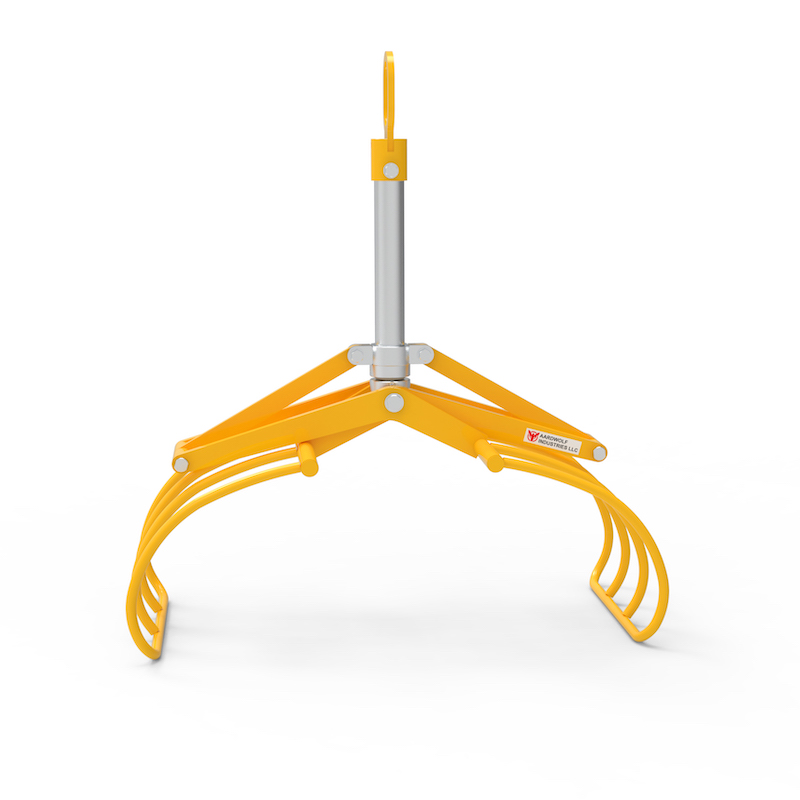

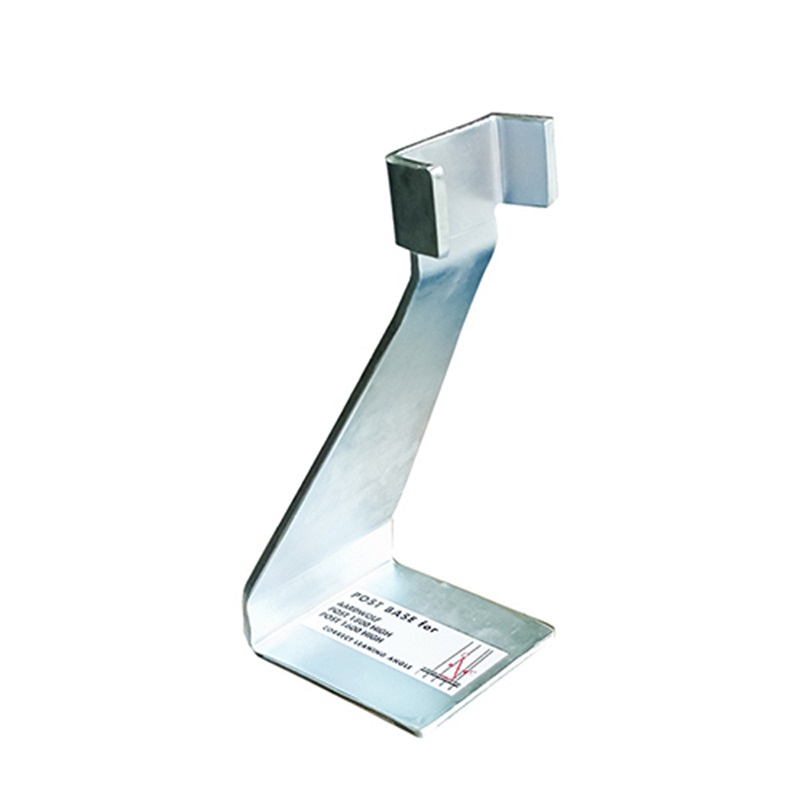

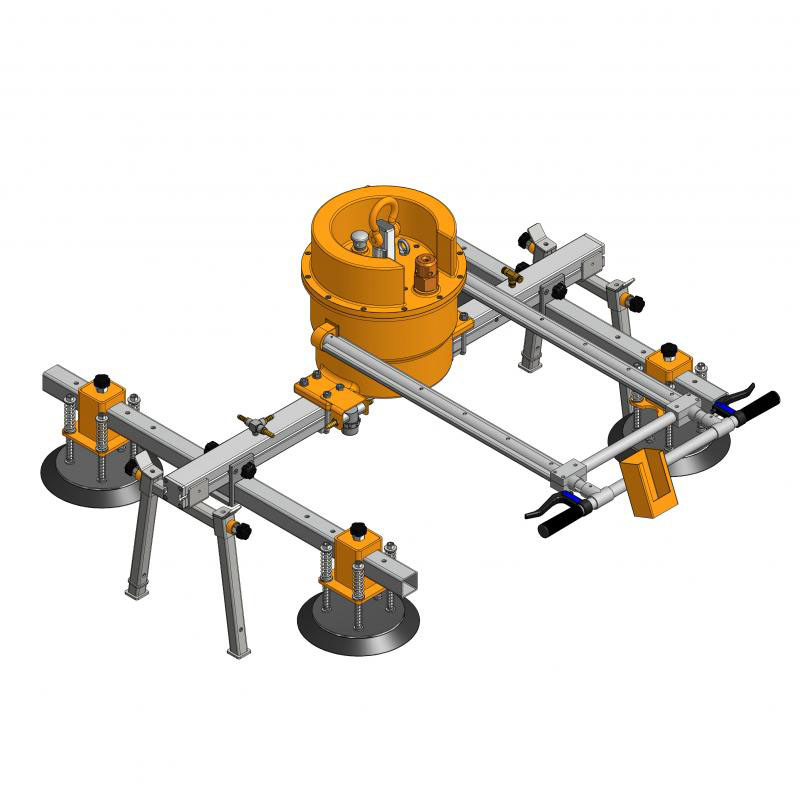

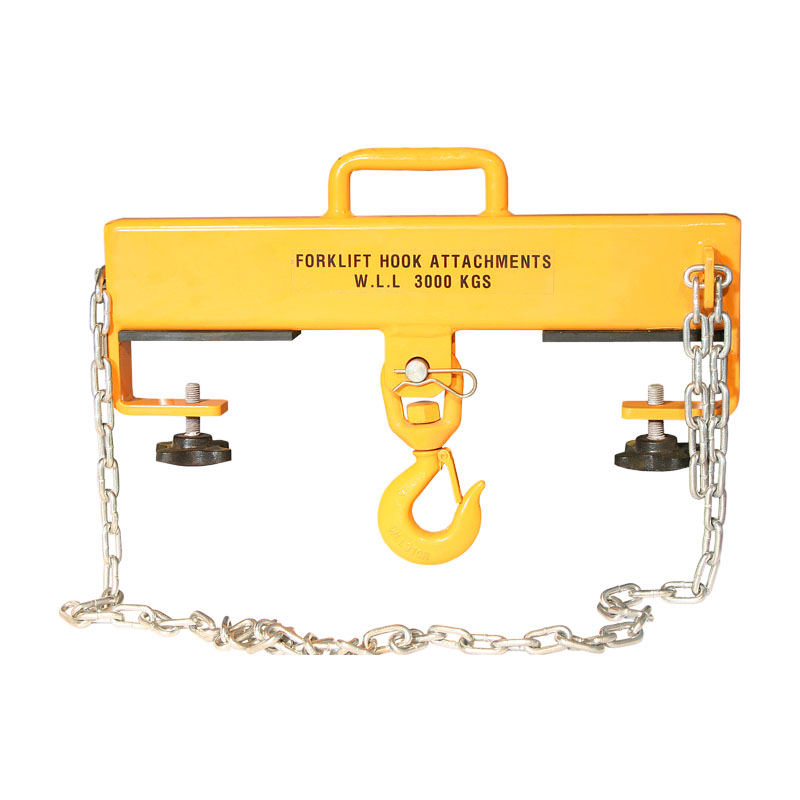

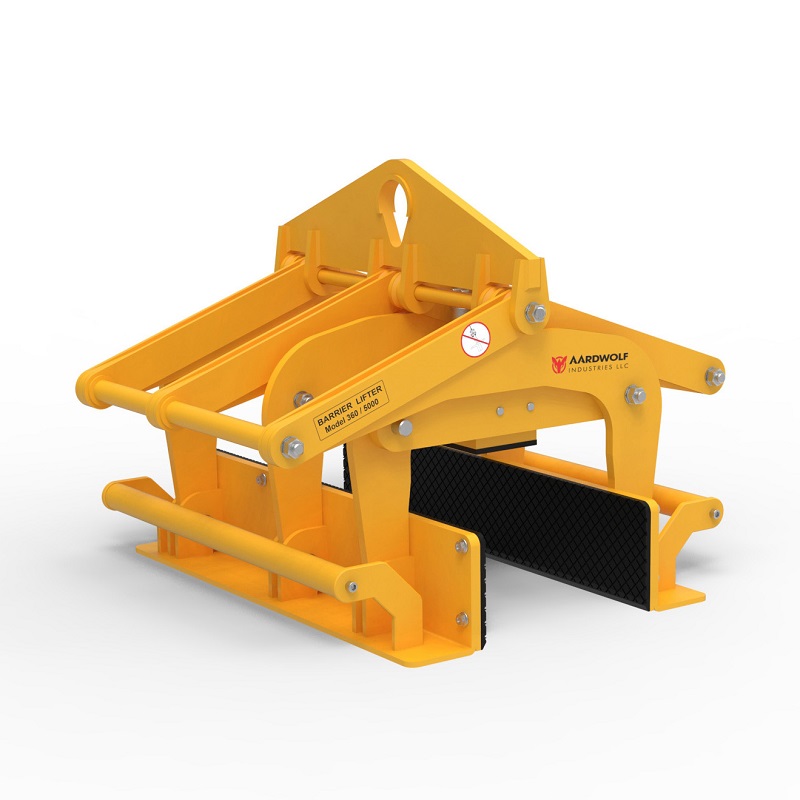

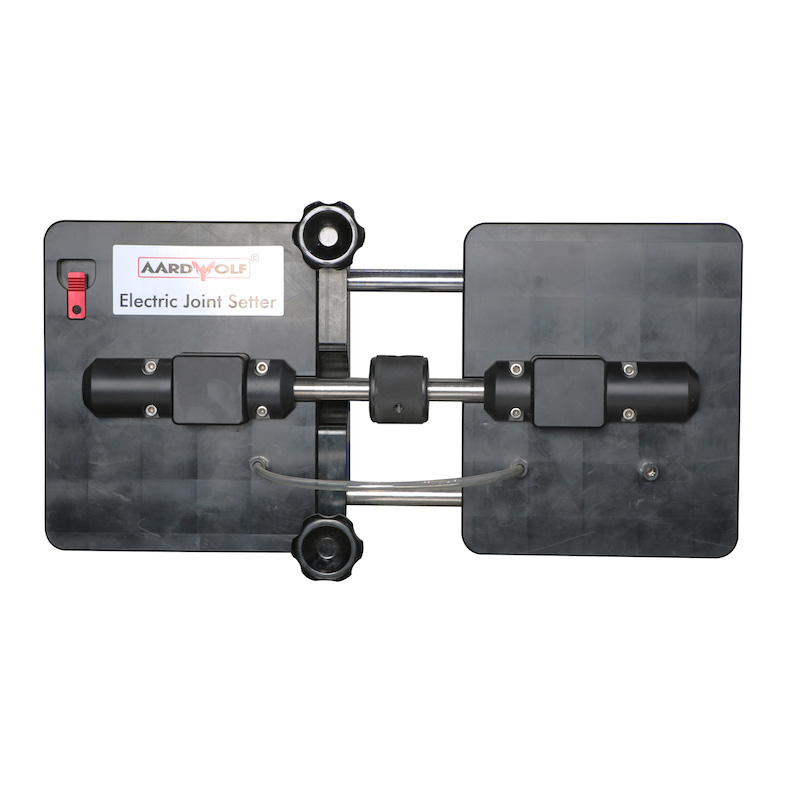

Introducing the Aardwolf Box Lifting Clamp

Revolutionizing How We Lift Boxes

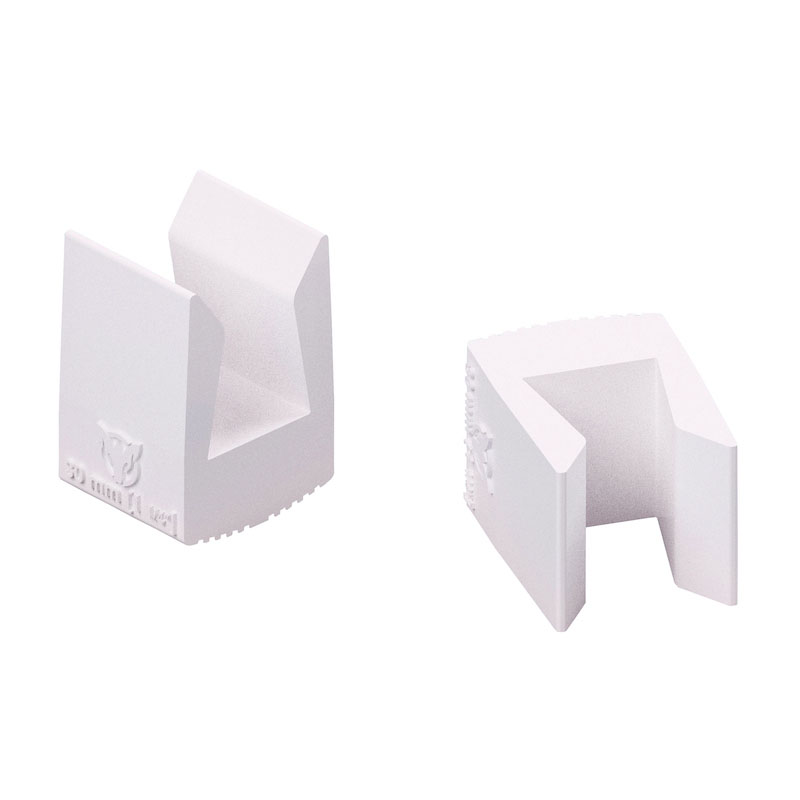

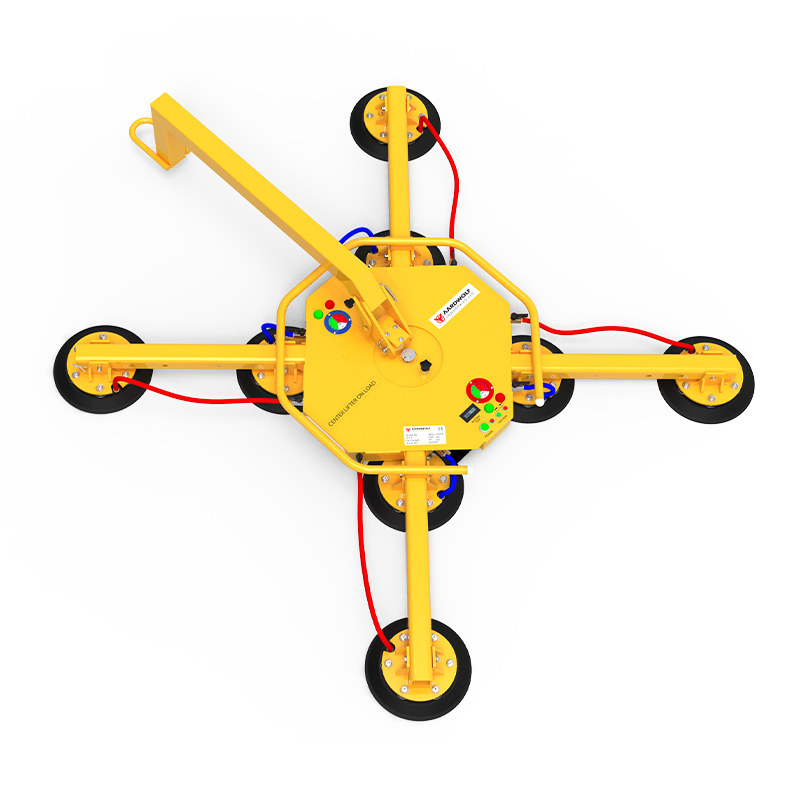

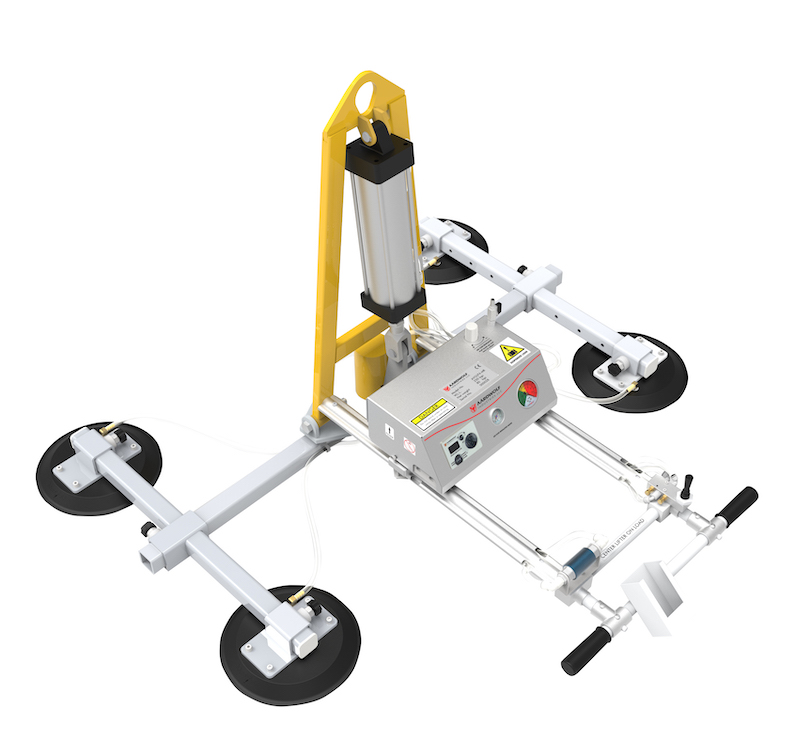

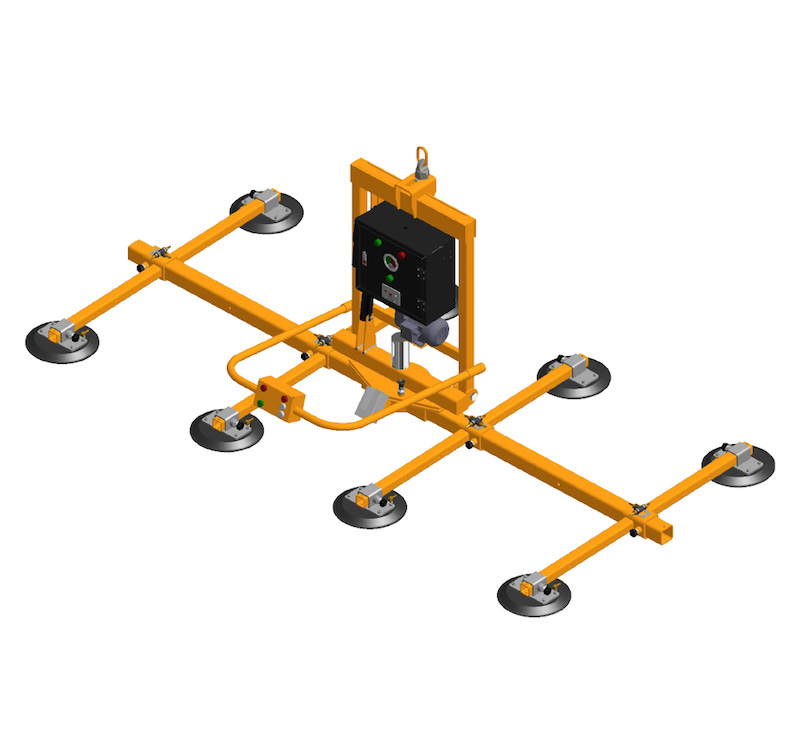

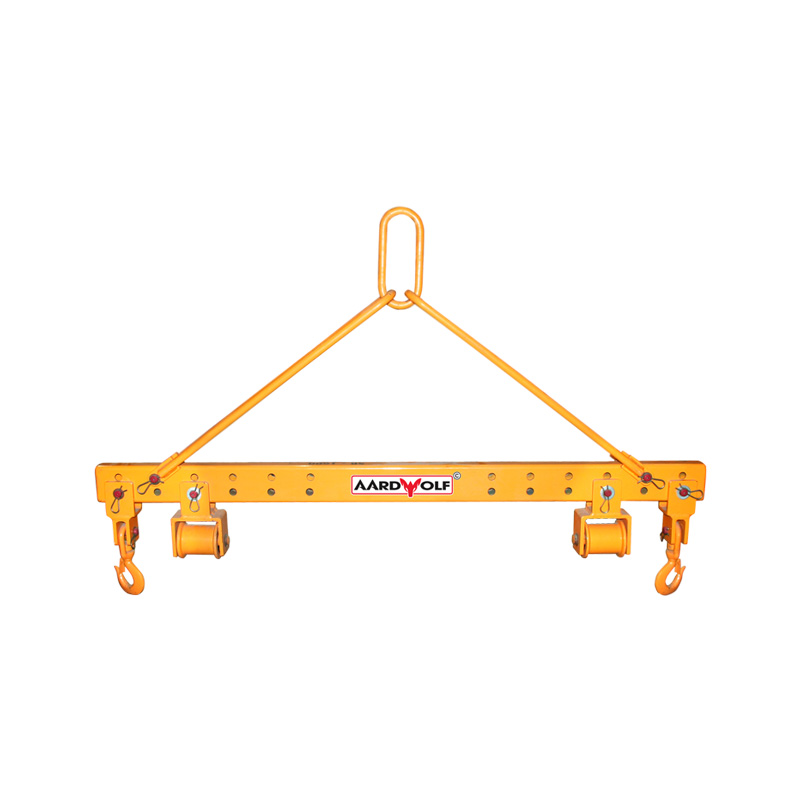

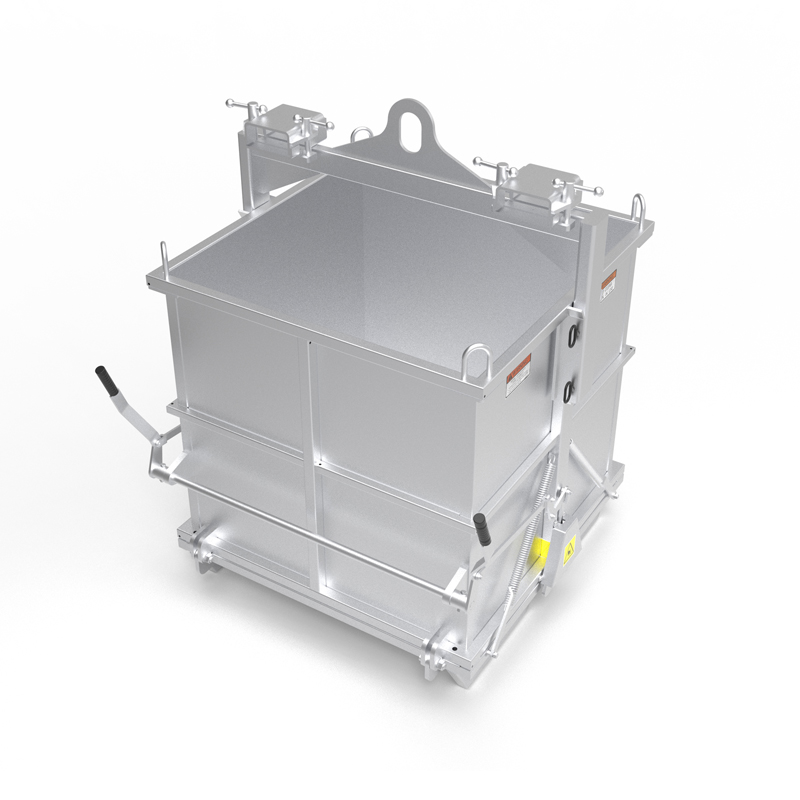

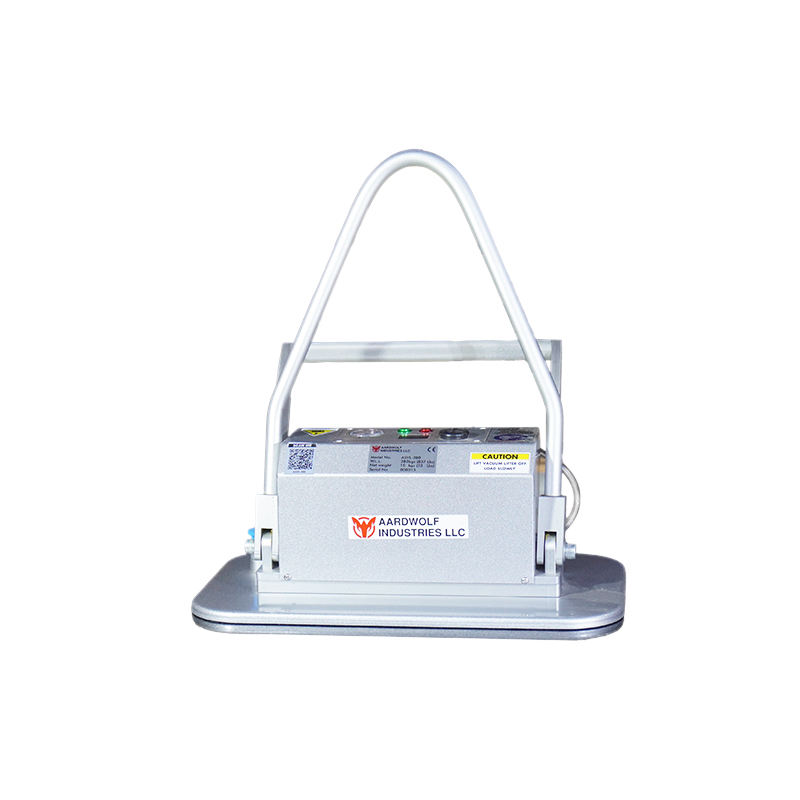

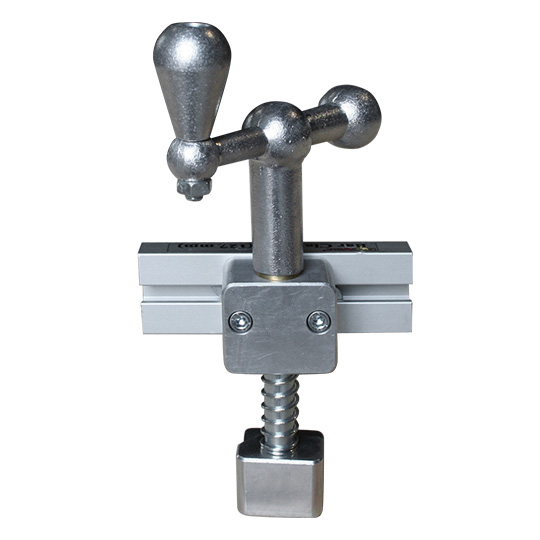

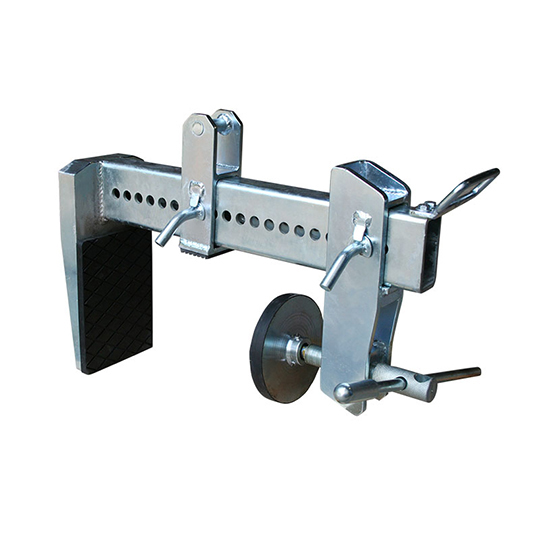

One of the most innovative solutions on the market today is the Aardwolf Box Lifting Clamp. This specialized clamp is designed to make lifting boxes safer, easier, and more efficient. By combining robust engineering with ergonomic design, the Aardwolf clamp addresses the core challenges faced by the material handling industry.

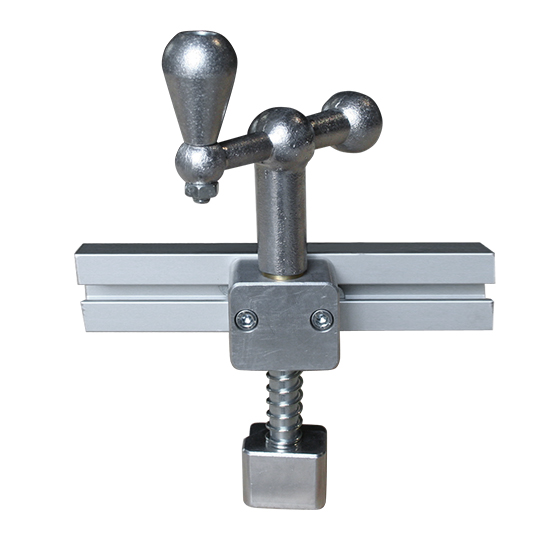

Key Features of the Aardwolf Box Lifting Clamp

-

Secure Grip: The clamp’s advanced gripping mechanism ensures a tight hold on various box materials and sizes, minimizing the risk of slippage.

-

Easy Operation: Simple controls and an intuitive design allow workers to use the clamp without extensive training.

-

Versatility: From lightweight cardboard cartons to heavier, bulkier boxes, the clamp is adaptable to a wide range of lifting needs.

-

Enhanced Safety: Built-in safety features protect both the operator and the materials, aligning with industry standards for material-handling equipment.

Benefits for Material Handling Companies

-

Reduced Labor Costs: With the clamp doing most of the heavy lifting, fewer workers are needed for manual handling, leading to cost savings.

-

Less Product Damage: A stable, secure grip ensures boxes remain intact, cutting down on wasted products and returns.

-

Increased Worker Morale: Operators benefit from reduced physical strain, leading to a healthier, more motivated workforce.

Conclusion

Efficient lifting boxes processes are the cornerstone of effective material handling in any industry. By investing in high-quality material handling equipment, such as the Aardwolf Box Lifting Clamp, businesses can revolutionize their workflows, prioritize safety, and remain competitive in a rapidly evolving marketplace. Whether you’re a small-scale operation or a large manufacturing facility, embracing modern lifting equipment solutions will ensure that your team is equipped to handle material challenges both now and in the future.

Follow us on: