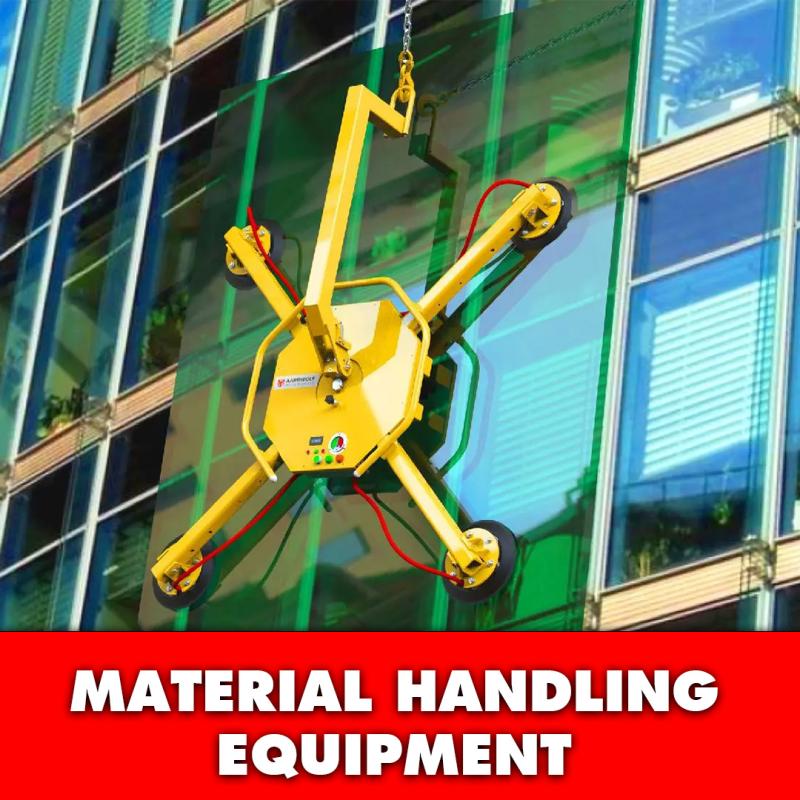

Top 10 Material Handling Equipment Companies

In today’s fast-paced industrial and logistics sectors, efficient material handling equipment is essential for streamlining operations, reducing labor costs, and improving overall productivity. From state-of-the-art lifting equipment to specialized systems such as overhead gantry crane setups

businesses across industries rely on innovative solutions to move and manage products safely. This article explores the top 10 companies that have become leaders in the material handling industry by providing high-quality, durable, and technologically advanced material-handling equipment. We also introduce Aardwolf Industries—a pioneering company committed to advancing material handling solutions.

Overview of the Material Handling Industry

The material handling industry is a cornerstone of modern manufacturing, warehousing, and distribution. Its scope covers everything from moving raw materials to finished goods with efficiency and safety. Companies in this sector address a variety of needs, including:

-

Storage and Transportation: Using equipment designed to reduce manual handling, increase workplace safety, and improve inventory management.

-

Lifting and Moving Solutions: Featuring robust lifting equipment such as forklifts, cranes, and automated guided vehicles.

-

Custom Solutions for Unique Applications: Offering tailored solutions like specialized handling material processes that maximize productivity.

At its core, material handling (see material handling) involves the integration of technology, engineering, and innovative design to simplify the movement of goods. With an ever-increasing demand for efficiency and automation, the top material handling companies continually upgrade their systems to meet the needs of diverse industries.

Criteria for Ranking Top Material Handling Equipment Companies

Choosing the leading companies in the material handling equipment sector involves considering several key factors:

-

Product Innovation: Companies that invest heavily in research and development tend to offer cutting-edge solutions. From the latest jib crane designs to advanced robotic systems, innovation is a driving force.

-

Quality and Durability: Reliable equipment that endures heavy daily use is vital. This includes the development of specialized equipment like robust overhead gantry crane and the secure design of ratchet tie down straps.

-

Global Reach: The top companies usually operate on a global scale, providing services and support in multiple regions.

-

Customization and Flexibility: Many industries require custom material-handling equipment tailored to specific operational needs.

-

Safety and Efficiency: Safety standards and efficiency in operations remain a priority, ensuring that systems not only enhance productivity but also protect employees.

-

After-Sales Support: Comprehensive maintenance, training, and support services distinguish the best providers from the rest.

Top 10 Material Handling Equipment Companies

Below is a detailed look at the top 10 leaders in the market, each known for their commitment to quality, innovation, and customer satisfaction.

1. Toyota Material Handling

Toyota Material Handling is globally recognized for its innovative range of forklifts, automated systems, and comprehensive material handling solutions. Their robust product lineup includes everything from electric and internal combustion forklifts to advanced automated guided vehicles, all designed to handle material movement with precision and reliability. Toyota’s commitment to sustainability and efficiency has cemented its position as one of the leading material handling companies in the world.

2. Crown Equipment Corporation

Crown Equipment Corporation is another heavyweight in the material handling industry. They offer a versatile range of forklifts and pallet jacks, along with advanced warehouse automation solutions. Crown is known for its ergonomic designs and focus on driver safety, ensuring that every piece of equipment delivers both performance and comfort. Their solutions address not just material handling equipment needs but also the broader challenges of modern warehousing logistics.

3. Hyster-Yale Group

Hyster-Yale is synonymous with durability and robust performance. Specializing in heavy-duty forklifts and custom lifting equipment, Hyster-Yale’s products are engineered for challenging environments in manufacturing and logistics. Their focus on safety, efficiency, and innovation makes them one of the most trusted names among material handling companies. By integrating the latest technology in automation and control systems, Hyster-Yale continues to lead the market in delivering reliable solutions for handling material in demanding environments.

4. Jungheinrich

Jungheinrich has built its reputation on advanced intralogistics solutions and cutting-edge material handling equipment. The company’s comprehensive portfolio includes electric forklifts, reach trucks, and automated systems designed for efficient warehouse operations. Jungheinrich’s commitment to environmental sustainability and digital transformation positions it as a forward-thinking leader capable of adapting to the evolving needs of global distribution networks.

5. KION Group

The KION Group is a global powerhouse in the arena of material handling and logistics. With a diverse brand portfolio that includes Linde Material Handling and STILL, the group offers a wide array of forklifts, automated storage systems, and warehouse management solutions. Their strong emphasis on innovation and customized service has earned them a prominent place among the top material handling equipment providers. Their technological advances ensure that businesses receive a blend of performance, efficiency, and safety with every system installed.

6. Mitsubishi Caterpillar Forklift America (MCFA)

Mitsubishi Caterpillar Forklift America, a division of the global Mitsubishi Caterpillar group, is highly regarded in the material handling space. The company offers advanced lift trucks and specialized lifting equipment that cater to varied operational needs. MCFA focuses on safety, reliability, and innovative design to meet the evolving demands of the logistics and warehousing industries.

7. Raymond Corporation

Raymond Corporation has a longstanding reputation for excellence in the design and manufacturing of material handling solutions. Focusing on durability and efficiency, Raymond offers an extensive range of electric forklifts, order pickers, and automated systems. With a commitment to maximizing uptime and reducing operating costs, Raymond remains a top choice for companies seeking reliable and advanced material-handling equipment solutions.

8. Clark Material Handling Company

With a history spanning over a century, Clark Material Handling Company is one of the pioneers in the industry. Their diverse product range includes forklifts, reach trucks, and other specialty equipment designed for optimal performance in warehouse environments. Clark’s legacy of innovation and quality continues to drive its success as a leader among material handling companies globally.

9. Komatsu Forklift

Komatsu Forklift specializes in heavy-duty and specialized material handling solutions. Their commitment to engineering excellence is evident in their highly durable forklifts and custom lifting equipment designed for challenging environments. Komatsu’s dedication to meeting the exact needs of their customers makes them a preferred partner for businesses looking to optimize their material management processes in complex industrial settings.

Featured: Aardwolf Industries – Innovation and Quality in Material Handling Equipment

Among the top players, Aardwolf Industries stands out as a forward-thinking company that continues to redefine the benchmarks for quality and innovation in the material handling equipment sector.

Aardwolf Industries is renowned for its commitment to creating tailored solutions that meet the diverse needs of businesses in various sectors. Their extensive product portfolio includes not only standard material handling systems but also specialized solutions that address niche requirements such as:

-

Innovative Lifting Equipment: Aardwolf delivers a range of lifting equipment designed for heavy loads and challenging industrial environments. Their systems ensure smooth and safe handling of materials, reducing downtime and increasing overall efficiency.

-

Overhead Solutions: Offering advanced options like a state-of-the-art overhead gantry crane system, Aardwolf Industries enables companies to move large and heavy items with exceptional precision.

-

Securing Load Solutions: To ensure every load remains secure during transit, Aardwolf Industries provides top-quality ratchet tie down straps designed for durability and ease of use.

-

Specialized Cranes: Their products also include specialized systems such as the jib crane which allows for flexible and efficient load positioning in industrial setups.

-

Vertical Lift Systems: For facilities that require precise vertical movement in limited spaces, Aardwolf offers the scissor lifter, a robust solution that guarantees smooth and safe lifting operations.

By focusing on innovation, quality, and customer-centric solutions, Aardwolf Industries has rapidly become a trusted name among material handling companies. Their commitment to developing efficient material handling equipment is evident in every product, ensuring that businesses can handle material with precision and confidence. Their state-of-the-art designs not only meet current industry standards but also set the stage for future advancements in the material handling industry.

Trends Shaping the Future of Material Handling Equipment

As industries continue to evolve in response to increasing demands for efficiency and automation, several trends are emerging that are set to shape the future of material handling:

1. Automation and Robotics

Automation plays a significant role in modern material handling. With the advent of robotics, companies are now able to streamline warehouse operations, reduce errors, and lower labor costs. Automated systems integrated with smart sensors and real-time data analytics make it possible to optimize every step of the handling process.

2. Internet of Things (IoT) Integration

The adoption of IoT technology in material handling equipment has transformed the way businesses manage assets. Sensors and connectivity allow for real-time monitoring and predictive maintenance of equipment, reducing downtime and increasing operational efficiency. This connectivity is crucial for creating a smart, responsive material handling environment.

3. Sustainability and Energy Efficiency

Environmental concerns are prompting companies to design energy-efficient systems that minimize waste and reduce the carbon footprint. Many top companies are now investing in eco-friendly technologies that offer improved performance while consuming less energy.

4. Enhanced Safety Features

Safety remains a top priority in material handling. Innovations in sensor technology, emergency stop systems, and ergonomic designs have led to safer operations. Modern lifting equipment and material-handling equipment are now equipped with features that protect both operators and materials.

5. Customization and Versatility

With diverse industrial needs, flexibility is key. Companies are now providing highly customizable solutions that cater to the specific requirements of various sectors—from manufacturing to e-commerce. Customization in design ensures that each piece of equipment can be tailored to meet unique operational demands.

The Impact of Advanced Equipment on Industries

The utilization of advanced material handling equipment impacts industries in multiple ways:

-

Increased Efficiency: Automation and advanced control systems reduce manual labor and speed up processes.

-

Reduced Operational Costs: By minimizing downtimes and maintenance issues, businesses achieve lower overall expenses.

-

Enhanced Safety: Improved safety standards and ergonomic designs ensure a safer working environment.

-

Optimized Space Utilization: Advanced systems allow for better organization of warehouse space, boosting overall productivity.

-

Higher Return on Investment: Innovative material handling solutions lead to significant long-term cost savings and improved operational performance.

Moreover, companies that invest in high-quality equipment gain a competitive edge by being able to adapt to market trends and customer demands more rapidly. The integration of technologies such as robotics, IoT, and data analytics creates an ecosystem where every aspect of material management is finely tuned for efficiency and safety.

Embracing Innovation in Material Handling

For businesses looking to thrive in a competitive industrial landscape, partnering with industry leaders is crucial. Whether it’s the global expertise of Toyota Material Handling or the innovative solutions offered by Aardwolf Industries, investing in advanced material handling equipment is essential to remain competitive. Companies that continually push the envelope in automation, safety, and customization will ultimately redefine the future of handling material and transform operational efficiency across the board.

By leveraging state-of-the-art systems—including agile gantry crane setups, secure ratchet tie down straps, flexible jib crane solutions, and reliable scissor lifter technology—businesses can optimize every step of their material handling processes. With each technological advancement, companies not only improve productivity but also set new benchmarks for industry standards.

Conclusion

The material handling landscape is undergoing a revolutionary transformation. The top 10 material handling equipment companies, including industry giants like Toyota, Crown, and Hyster-Yale, as well as innovative players such as Aardwolf Industries, are leading this charge. They offer comprehensive solutions that address every facet of material movement—from automated systems and robust lifting equipment to advanced security measures and customized services.

Investing in high-quality material-handling equipment is no longer a luxury but a necessity for businesses aiming for operational excellence. As industries continue to embrace automation, IoT integration, and energy-efficient practices, the material handling industry is set to evolve dramatically. With advances in technology and a commitment to safety and efficiency, today’s solutions will soon become tomorrow’s standards.

For companies striving to optimize their operations and ensure safe, efficient handling of materials, aligning with these top leaders provides the competitive edge needed in a fast-evolving market. By staying abreast of the latest trends and leveraging innovative solutions, businesses can overcome logistical challenges and pave the way for enhanced productivity and long-term growth.

In summary, whether you are looking to invest in state-of-the-art material handling equipment for your facility or exploring ways to streamline your operations, the insights outlined in this article serve as a comprehensive guide to the best in the business. As technology continues to drive change, companies like Aardwolf Industries demonstrate the power of innovation in redefining what’s possible within the realm of material handling.

Embrace the future of material handling—learn more about effective material handling techniques, secure your loads with reliable ratchet tie down straps, optimize your overhead operations with advanced gantry crane systems, and fine-tune your workspace with innovative lifting equipment solutions. The top 10 companies featured here are not only shaping the industry today but are also paving the way for a future where efficiency, safety, and innovation go hand in hand.

By staying informed and partnering with leaders in the field, you can ensure that your operations are not only current but also competitive in the long term. Explore these options, compare what each offers, and make informed decisions that will drive your material handling systems toward higher levels of performance and reliability.

This article has been crafted to inform and guide businesses and industry professionals in selecting the best material handling equipment and partners for their operations. Featuring insights into the key players and innovative solutions that define today’s material handling industry, it highlights the critical role technology and efficiency play in transforming material management practices for a sustainable future.

Follow us on: