How to Install a Jib Crane Step-by-Step Guide

A jib crane is a pivotal piece of lifting equipment commonly used within the material handling industry. It features a horizontal jib or boom, supporting a movable hoist, allowing operators to lift and maneuver heavy materials within a specified radius

Installing a jib crane significantly enhances efficiency and safety in various industrial settings by simplifying the process of material handling. This guide provides a comprehensive step-by-step approach to installing a jib crane, ensuring your workspace meets safety standards and boosts productivity.

Understanding Jib Cranes and Their Benefits

A jib crane is a pivotal piece of lifting equipment commonly used within the material handling industry. It features a horizontal jib or boom, supporting a movable hoist, allowing operators to lift and maneuver heavy materials within a specified radius. Compared to other lifting equipment like gantry cranes and scissor lifters, jib cranes offer enhanced maneuverability and are particularly beneficial for confined workspaces.

Advantages of Jib Cranes

-

Improved efficiency in handling material.

-

Space-saving due to their compact design.

-

Flexibility in positioning and rotation.

-

Reduced labor and enhanced workplace safety.

Pre-Installation Considerations

Before installing your jib crane, thorough preparation is critical. Evaluate the following elements to ensure seamless installation:

Load Capacity and Usage Requirements

Determine the maximum load weight the crane will handle. Choosing the appropriate crane capacity is crucial for safe and effective material handling operations.

Site Analysis

Perform a detailed assessment of your workspace, considering available space, ceiling height, and proximity to other equipment or structures. Ensure the selected site complies with safety and operational standards required by material handling companies.

Foundation Requirements

The jib crane’s stability and performance depend significantly on its foundation. Ensure the site’s floor or wall structure can withstand the crane’s load and operational stresses.

Tools and Equipment Needed

Having the correct tools at your disposal simplifies the installation process. Key tools include:

-

Torque wrench

-

Drill machine

-

Level

-

Ratchet tie down straps (learn how to use ratchet tie down straps)

-

Safety equipment (gloves, goggles, helmets)

Step-by-Step Guide to Installing a Jib Crane

Step 1: Inspect and Prepare Components

Upon receiving your jib crane, carefully inspect all components. Check for damages and verify all necessary parts according to the manufacturer’s checklist.

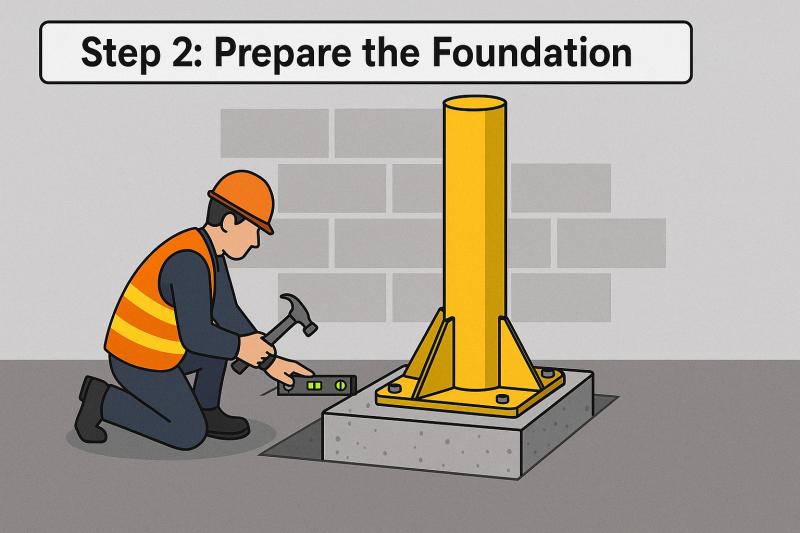

Step 2: Prepare the Foundation

The foundation is critical for jib crane installation. Depending on whether you have a freestanding or wall-mounted jib crane, prepare the concrete foundation or wall supports accordingly. Ensure all mounting surfaces are level and meet specified load-bearing criteria.

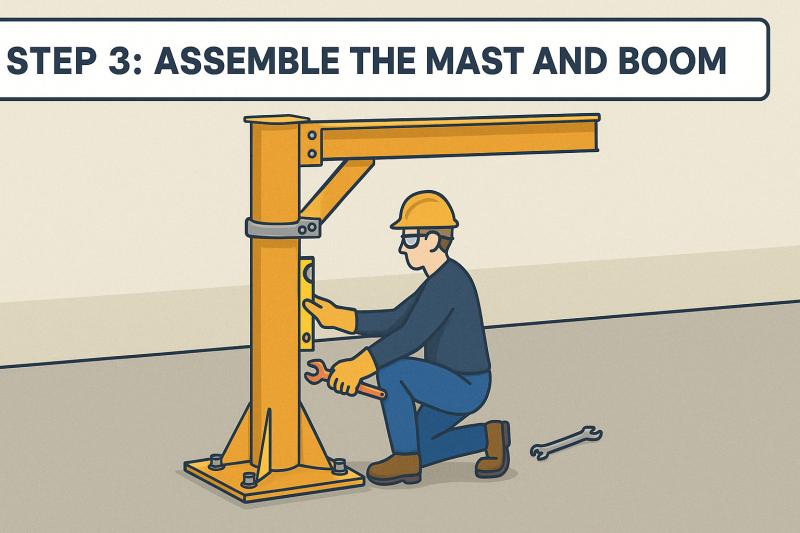

Step 3: Assemble the Mast and Boom

Follow the manufacturer's guidelines closely while assembling the mast and jib on crane. Typically, the mast will first be securely mounted to the foundation or wall bracket, ensuring it is perfectly vertical using a level.

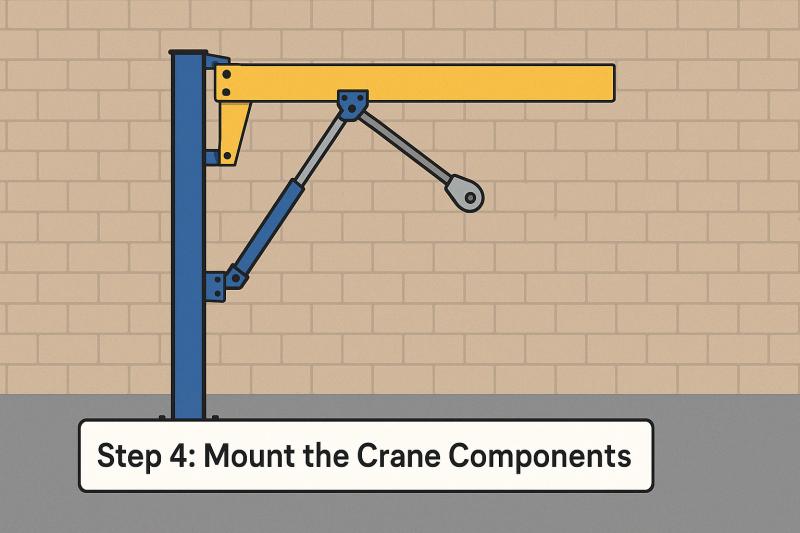

Step 4: Mount the Crane Components

Attach the boom or jib to the mast securely. Ensure all bolts and connections are tightened to manufacturer specifications using a torque wrench.

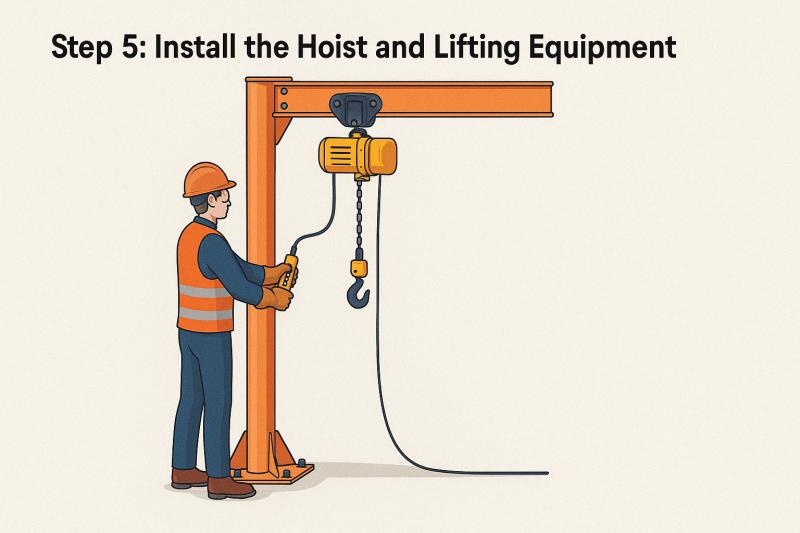

Step 5: Install the Hoist and Lifting Equipment

Mount the hoist onto the jib crane following the manufacturer's instructions. Connect all electrical or pneumatic lines required for the hoist operation. Ensure all components move smoothly and without obstructions.

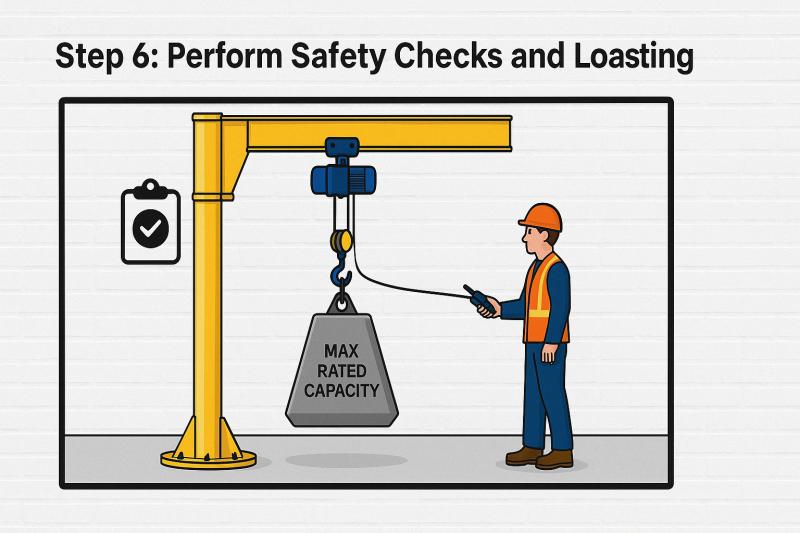

Step 6: Perform Safety Checks and Load Testing

Conduct thorough safety inspections to confirm all bolts and joints are securely fastened. Complete a load test using the crane’s maximum rated capacity to ensure safe operation and compliance with industry standards.

Post-Installation Best Practices

Regular Maintenance

Proper maintenance extends the lifespan of your jib crane and ensures continued safe operation. Regularly inspect your jib crane for signs of wear, including checking bolts, hoists, and cables for optimal material handling.

Operator Training

Ensure operators receive thorough training in jib crane operation and safety practices. Proper handling reduces accidents and maintains productivity in material-handling environments.

Comparison with Other Material Handling Equipment

While jib cranes are highly effective, evaluating other material-handling equipment such as portable gantry cranes or scissor lifters is beneficial for comprehensive material handling solutions.

-

Portable Gantry Crane: Ideal for temporary or movable lifting requirements due to their portability.

-

Scissor Lifter: Suitable for vertical lifting tasks, particularly in tight spaces.

Understanding these alternatives allows businesses to choose the best equipment for their specific needs and workspace configurations.

Industry Applications of Jib Cranes

Jib cranes are widely used across various sectors within the material handling industry, including manufacturing, construction, warehouses, automotive assembly, and shipping docks. Their versatility in handling diverse loads makes them a critical component in efficient operations.

Choosing the Right Jib Crane Supplier

Partnering with reliable material handling companies ensures the quality and reliability of your equipment. Look for suppliers offering:

-

Comprehensive technical support

-

Warranty and after-sales services

-

Training programs for safe crane operation

Conclusion

Installing a jib crane significantly enhances the efficiency, safety, and productivity of material handling operations. By following this step-by-step installation guide, businesses can confidently integrate jib cranes into their workflows, benefiting from improved operational effectiveness and workplace safety.

Follow us on: