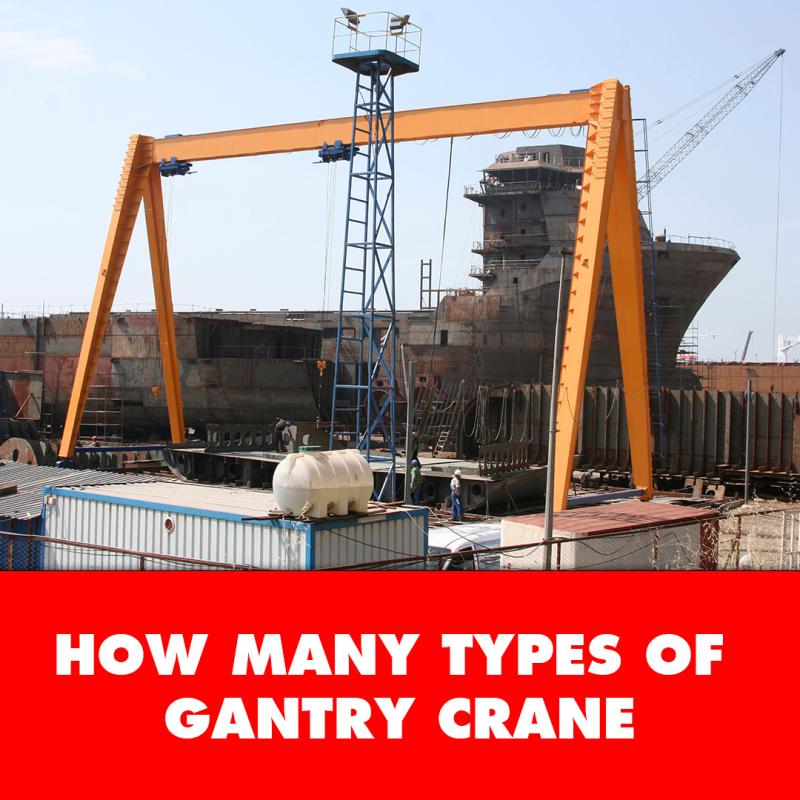

How Many Types of Gantry Crane

Gantry cranes are a cornerstone of modern material handling and industrial operations. These versatile machines come in various forms, each engineered to suit specific operational needs—from heavy lifting in large ports to mobile solutions on construction sites.

In this article, we explore the many types of gantry crane, dive deep into their features and applications, and provide insights on how they compare with other crane systems, such as jib crane setups. Whether you are evaluating a fixed gantry crane for your facility or considering a more dynamic mobile gantry crane, this guide is crafted to help you understand the differences, advantages, and unique applications of each type.

Introduction to Gantry Cranes

Gantry cranes are overhead lifting machines that run on tracks and are often found in shipyards, docks, and warehouses. Their robust design allows them to handle heavy loads and maneuver goods over large distances with precision. Gantry cranes differ from typical overhead cranes in that they usually have a self-supporting structure that spans both sides of the area being serviced. This design eliminates the need for a building or a separate runway structure, giving gantry cranes flexibility and ease of installation in open spaces.

The benefits of gantry cranes include:

-

Versatility: They are available in fixed, portable, and mobile variations to suit different operational needs.

-

Durability: Designed to handle heavy loads, gantry cranes are built for longevity even in demanding environments.

-

Mobility: Options such as gantry crane mobile provide on-site flexibility.

In today’s competitive environment, optimizing material handling equipment like gantry cranes can significantly boost productivity and efficiency in operations.

Overview of Gantry Crane Applications

Gantry cranes play a vital role in several industries, including:

-

Shipping and Logistics: Large container gantry cranes are ubiquitous in ports and shipping terminals, where they load and unload container ships.

-

Construction: Portable and mobile gantry cranes are essential on construction sites for lifting materials and equipment.

-

Manufacturing and Warehousing: Overhead gantry cranes streamline the movement of heavy raw materials and finished products within large facilities.

Their inherent design advantages have made gantry cranes indispensable in scenarios where space is at a premium or where heavy-duty lifting tasks are required without permanent infrastructure investments.

What is a Gantry Crane?

A gantry crane is a type of overhead crane that utilizes a complete frame or gantry structure to support the lifting mechanism. This frame typically straddles the workspace, with wheels or rollers that travel along fixed tracks on the ground. The design enables cranes to have a long span and provides significant lifting power for heavy loads.

For those new to the industry, understanding the concept of a gantry crane helps demystify the similarities and differences between it and other types of cranes, such as the jib crane or even mobile construction cranes.

Types of Gantry Cranes

Gantry cranes are not a one-size-fits-all solution. They come in various types, each optimized for distinct functions and operational environments. Below is a detailed look at the most common types.

Container Gantry Crane

Container gantry cranes are perhaps the most recognized type in global logistics. These cranes are specifically designed for the handling of shipping containers in port operations. Their robust build and high precision allow them to load and unload container ships efficiently.

Key Features:

-

High Lifting Capacity: Engineered to handle containers weighing several tonnes.

-

Wide Span: Their design accommodates containers from various shipping lines.

-

Automation Integration: Many container gantry cranes feature automated systems to improve cycle times and enhance safety.

These cranes are critical in port logistics, as they not only streamline the loading and unloading process but also maintain the pace of global trade.

Gantry Crane Portable

Portable gantry cranes are designed for flexibility and ease of transport. Their lightweight design and often modular construction enable them to be quickly set up and dismantled at different job sites. This type of gantry crane is particularly suitable for temporary installations in construction or maintenance projects.

Key Benefits:

-

Quick Deployment: Ideal for projects requiring short-term lifting solutions.

-

Ease of Assembly: Minimal infrastructure is needed, which speeds up setup.

-

Versatility: Can be used in confined spaces where permanent cranes cannot be installed.

These portable units offer a balance between lifting capacity and mobility, making them a popular choice in dynamic work environments. Many professionals search for solutions like a "portable gantry crane" when flexibility and adaptability are key.

Gantry Crane Mobile

Mobile gantry cranes combine the lifting power of a standard gantry crane with the mobility of a truck or a rail system. This type is often used in logistics centers or large facilities where the crane needs to move along a predetermined path to service multiple areas.

Advantages:

-

On-Demand Movement: Easily relocate within a facility to cover various work zones.

-

Enhanced Operational Efficiency: Saves time by reducing the need for multiple cranes in different sections.

-

User-Friendly Controls: Most mobile units come with advanced control systems for precise handling.

The mobile gantry crane offers a flexible solution for material handling, allowing operators to shift seamlessly from one area of a facility to another.

Overhead Gantry Crane

Often confused with standard overhead cranes, the overhead gantry crane is distinct in that its support structure is independent of any building structure. This makes it particularly useful in open environments such as ports and outdoor industrial sites.

Notable Features:

-

Free-Standing Design: Does not require a building structure for support.

-

Adaptability: Can be relocated or reconfigured with relative ease.

-

Robust Construction: Built to withstand outdoor conditions and heavy loads.

The versatility of the overhead gantry crane makes it an asset for operations that require long span lifting capabilities and flexible installation options.

Complementary Components and Related Technologies

Integration with Other Crane Systems

In many industrial applications, gantry cranes are part of a larger ecosystem that includes other types of cranes. For instance, gantry crane systems might work alongside jib crane installations. While gantry cranes handle the heavy, long-span lifting tasks, jib cranes are frequently used for more localized tasks in assembly lines and maintenance areas.

Use of Ratchet Tie Down Straps

Proper securing of loads is a crucial aspect of safe crane operation. Many operators use ratchet tie down straps to secure cargo during transport. These straps are essential in ensuring that heavy loads remain stable on the crane platform, reducing the risk of accidents during lifting and moving operations.

Comparisons with Other Lifting Equipment

Gantry cranes offer several advantages compared to other types of lifting equipment, particularly in terms of mobility and installation flexibility. For example, conventional overhead cranes are typically fixed in place, while mobile gantry cranes can navigate around obstacles and adapt to the variable needs of a dynamic environment. Additionally, the unique design of container gantry cranes enables them to operate efficiently in high-traffic port areas where constant movement and rapid load exchanges are the norms.

The Advantages of Different Gantry Crane Types

When selecting a gantry crane for your operations, it is essential to consider several factors such as load capacity, mobility, and the installation environment. Below, we delve into the advantages of each type.

Advantages of Container Gantry Cranes

-

High Throughput: Designed for efficiency in container terminals, these cranes are built to keep pace with the high volume of cargo handled daily.

-

Specialized Design: Their design specifically caters to the dimensions and weight of standard shipping containers, ensuring a perfect fit for port logistics.

-

Technological Integration: Modern container gantry cranes incorporate automation, remote control, and intelligent systems that boost overall operational efficiency.

Advantages of Portable and Mobile Gantry Cranes

-

Flexibility: Both portable and mobile gantry cranes offer the flexibility to be moved and configured as needed. This is particularly beneficial in construction and temporary installation scenarios.

-

Space Efficiency: Their design allows for operation in confined spaces where larger, fixed cranes would be impractical.

-

Cost-Effective: Due to their adaptability and ease of setup, these cranes can be a more cost-effective solution compared to permanently installed systems.

Advantages of Overhead Gantry Cranes

-

Installation Flexibility: With a free-standing design, overhead gantry cranes can be installed without major alterations to existing facilities. This makes them ideal for retrofitting solutions.

-

Robust Performance: Their ability to operate under severe weather conditions and handle extreme loads makes them a dependable choice for outdoor and high-volume industrial operations.

-

Scalability: Companies can invest in overhead gantry cranes with the confidence that the system can be scaled or reconfigured as their operational requirements evolve.

Considerations for Choosing the Right Gantry Crane

Operational Environment

The first factor to consider when choosing a gantry crane is the environment in which it will operate. Port operations, for instance, demand large container gantry cranes that can handle continuous, heavy-duty usage. In contrast, a construction site might benefit more from a portable gantry crane or mobile gantry crane solution that can be relocated with ease.

Load Capacity and Lifting Height

Understanding the specific weight and size of the loads is crucial. Operating a gantry crane in a facility that requires the transfer of extremely heavy components calls for a crane with an appropriate load capacity and lifting height. Overhead gantry cranes typically offer excellent height capabilities, making them useful for industries with tall storage configurations or multilevel operations.

Mobility and Space Constraints

The choice between a fixed and a mobile gantry crane often comes down to the spatial layout of your operation. For instance:

-

Fixed Installation: Ideal for environments where the crane remains in a designated spot, delivering consistent performance day after day.

-

Mobile Configuration: Offers the benefit of shifting across different areas within a facility, maximizing the utility of the crane for varied tasks. The terms "gantry crane mobile" and "mobile gantry crane" are often used interchangeably to refer to these agile systems.

Cost and Installation Time

Budget considerations and installation time are also essential factors. While a dedicated container gantry crane might be more expensive due to its specialized nature and high load capacity, a portable gantry crane provides a more flexible and economical solution for temporary projects. Quick deployment not only saves time but also minimizes downtime in operational workflows.

Safety Features and Technological Enhancements

Modern gantry cranes come equipped with advanced safety features to prevent accidents and optimize operations. Some of these features include:

-

Load Monitoring Systems: Ensure the crane does not exceed its rated capacity.

-

Automated Controls: Enable precision in operations and reduce human error.

-

Anti-Collision Sensors: Increase safety when multiple cranes operate in proximity.

In addition, integrating technologies such as IoT sensors and remote monitoring can further enhance the operational efficiency and safety of gantry cranes.

Integrating Gantry Cranes with Broader Material Handling Systems

Gantry cranes do not work in isolation. In many industrial settings, they are part of a broader material handling system. This system can include robotic arms, conveyor belts, and automated guided vehicles (AGVs) that work in concert to move and process materials seamlessly.

Synergies with Other Crane Systems

Pairing gantry cranes with other types of cranes, such as the jib crane, creates a robust material handling network. While gantry cranes take on heavy-duty loads across wide spans, jib cranes can handle more precise, localized tasks. This synergy not only enhances overall operational efficiency but also provides flexible solutions tailored to specific needs.

Enhancing Efficiency with Proper Securing Techniques

When operating any crane, the safe securing of loads is paramount. Using ratchet tie down straps ensures that cargo is firmly held in place during lifting and transit. This is especially critical when dealing with heavy or irregularly shaped loads, where slippage or imbalance could lead to accidents or equipment damage.

Future Trends in Gantry Crane Technology

As industries evolve, so do the technologies underpinning material handling systems. Here are some future trends that are set to transform the operation of gantry cranes:

Automation and Remote Control

The integration of automation in gantry cranes is accelerating. Remote control functionality, often augmented with machine learning algorithms, is providing operators with tools for precise load handling in real-time. Automation not only enhances safety but also optimizes productivity by reducing the margin for human error.

Energy Efficiency and Sustainability

Future gantry cranes are likely to incorporate energy-efficient designs and renewable power sources. As environmental concerns drive regulatory changes and market preferences, manufacturers are focusing on creating cranes that offer both operational efficiency and a reduced carbon footprint.

Advanced Material and Structural Designs

The evolution of materials science is leading to stronger, lighter components for gantry cranes. Advanced composites and high-strength alloys enable manufacturers to build cranes that can handle greater loads without a corresponding increase in structural weight, ensuring both durability and mobility are maintained.

Connectivity and the Internet of Things (IoT)

The adoption of IoT technologies in industrial equipment is on the rise. Future gantry cranes could feature interconnected sensors that monitor operational metrics in real time. This connectivity paves the way for predictive maintenance, reducing downtime and extending the lifespan of the equipment.

Conclusion

Gantry cranes, whether in the form of the robust container gantry crane, the flexible portable gantry crane, or the agile mobile gantry crane, represent critical infrastructure in modern industrial operations. Their versatility and adaptability make them suitable for a wide range of applications—from busy port terminals to complex construction sites and expansive manufacturing facilities.

To summarize, the major types of gantry cranes include:

-

Container Gantry Crane: Optimized for port operations and handling standardized shipping containers.

-

Gantry Crane Portable: Designed for quick deployment and temporary installations, offering flexibility in transient work environments.

-

Gantry Crane Mobile (Mobile Gantry Crane): Combines high lifting capacity with mobility, ideal for operations requiring movement across various areas.

-

Overhead Gantry Crane: A free-standing design independent of building structures, perfectly suited for outdoor and expansive industrial settings.

Beyond these, integrating gantry cranes with complementary technologies—such as ratchet tie down straps for securing loads and utilizing systems like the jib crane for specialized tasks—creates a holistic material handling solution that can meet the diverse needs of modern industry.

By understanding the nuances of each gantry crane type, organizations can make informed decisions tailored to their specific operational requirements, ensuring efficiency, safety, and scalability in their material handling processes. Whether you are exploring the capabilities of a gantry crane for heavy-duty port logistics or considering a more flexible solution like a mobile system, the key lies in matching the crane’s capabilities to the task at hand.

Embracing future trends such as automation, improved energy efficiency, and IoT connectivity will further enhance the operational effectiveness of gantry cranes. As industries continue to evolve, staying abreast of technological advancements will be critical for maintaining a competitive edge, ensuring that your material handling system is not only current but also future-proof.

Investing in the right type of gantry crane today means setting up your operations for long-term success, improved productivity, and enhanced safety. With the insights provided in this guide, you are well-equipped to make informed decisions and optimize your material handling processes with the best-suited gantry crane solutions for your needs.

By exploring these categories and understanding their benefits, you can align your material handling strategy with the latest trends and technological innovations. Choose the ideal solution that brings together the best of strength, mobility, and flexibility to propel your operations forward in an increasingly competitive global market.

Remember, continuous innovation is reshaping the material handling landscape. Whether you are considering a fixed installation or a dynamic, reconfigurable system, gantry cranes remain at the forefront of industrial lifting technology—and the right selection can transform your operational efficiency.

This comprehensive guide provides an in-depth look into the various types of gantry cranes and how each can meet specific industry requirements. With a focus on both traditional and innovative designs, we hope this article serves as a valuable resource for anyone looking to understand or invest in gantry crane technology.

Follow us on: