Aardwolf Work Stations | Material Handling Efficiency

Efficient material handling is the cornerstone of modern industrial operations. As companies strive to optimize workflows and ensure safety, advanced material-handling equipment becomes essential. Aardwolf Work Stations are at the forefront of this evolution, offering innovative solutions designed to streamline the process of handling material while boosting productivity and safety in the material handling industry.

The Importance of Modern Material Handling

Modern industries rely on efficient material handling to stay competitive. Whether in warehouses, manufacturing plants, or logistics centers, the right equipment minimizes downtime and improves operational accuracy. For material handling companies, investing in reliable lifting equipment and versatile systems is key to handling material effectively and cost-efficiently.

Challenges in Material Handling

-

Safety Risks: Manual material handling can lead to injuries and accidents.

-

Operational Downtime: Inefficient systems slow down production and lead to higher costs.

-

Space Constraints: Maximizing available space is critical for smooth operations.

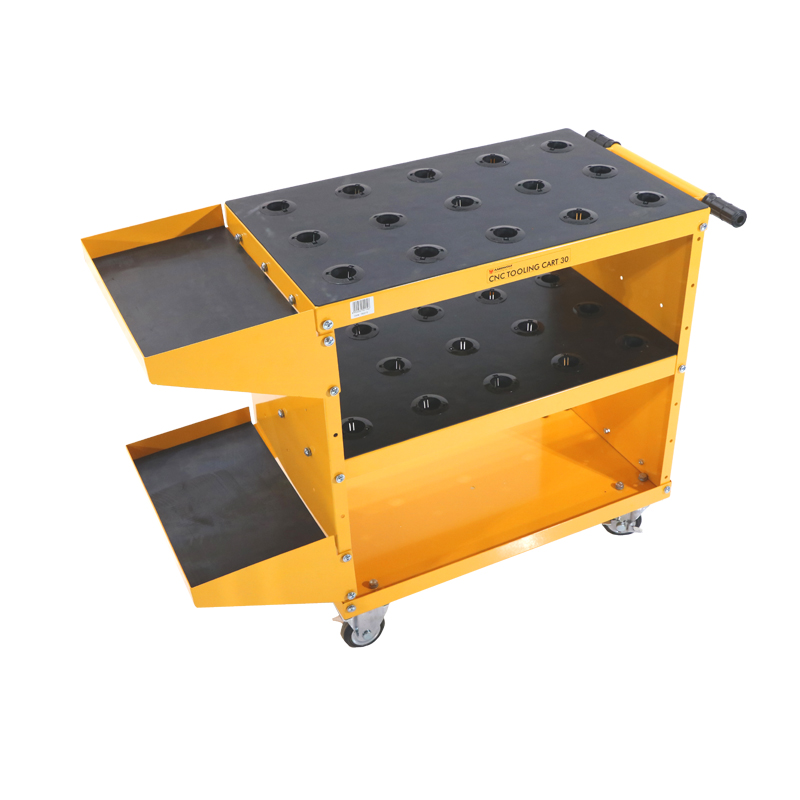

Introducing Aardwolf Work Stations

Aardwolf Work Stations are designed to address these challenges by providing a comprehensive solution that integrates seamlessly with existing material-handling equipment. These work stations are engineered to enhance the way businesses handle material, ensuring faster turnaround times and increased safety.

Core Benefits of Aardwolf Work Stations

-

Optimized Workflow: Their modular design allows for rapid assembly and reconfiguration, ensuring that your facility can adapt to changing needs.

-

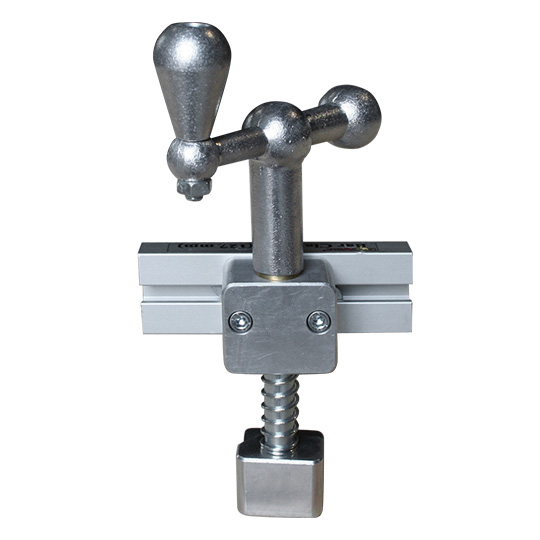

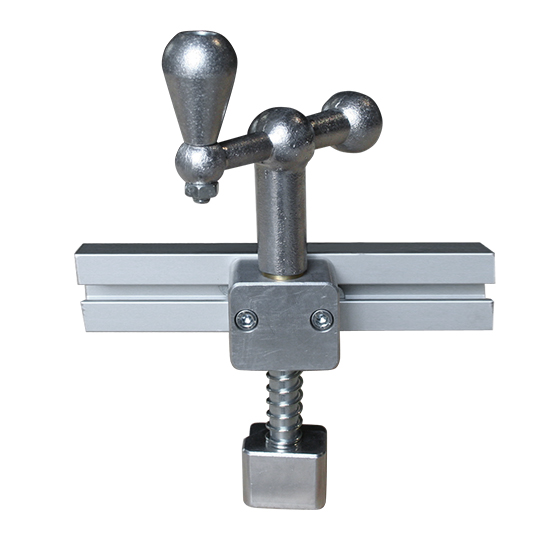

Enhanced Safety: Built with advanced safety features, these work stations reduce the risk of accidents and improve overall workplace safety.

-

Durability and Reliability: Constructed from high-quality materials, Aardwolf Work Stations are built to last, reducing maintenance costs over time.

-

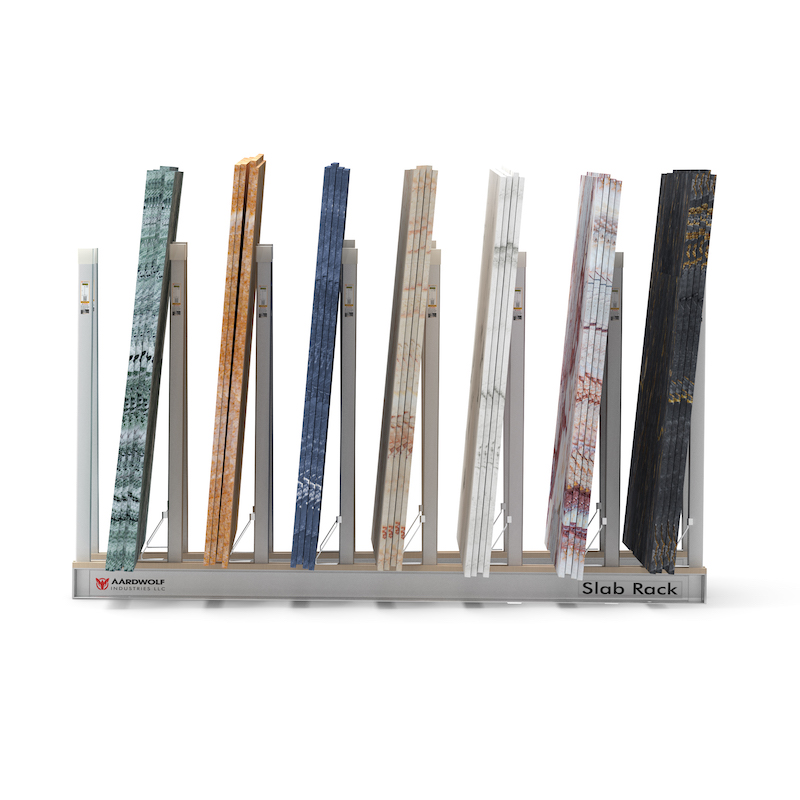

Space Efficiency: Designed to maximize storage and operational space, these work stations help you make the most of your facility.

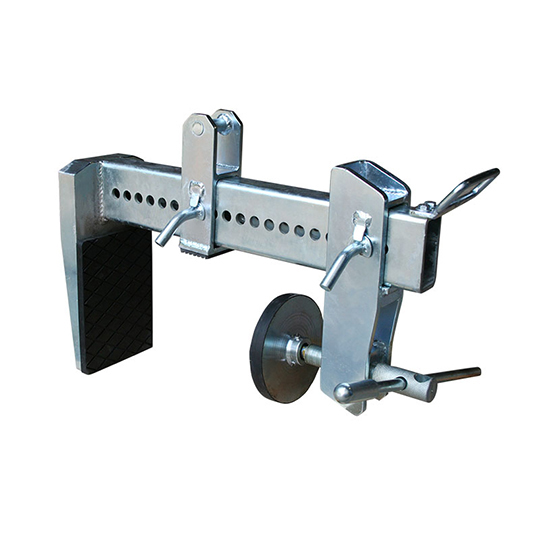

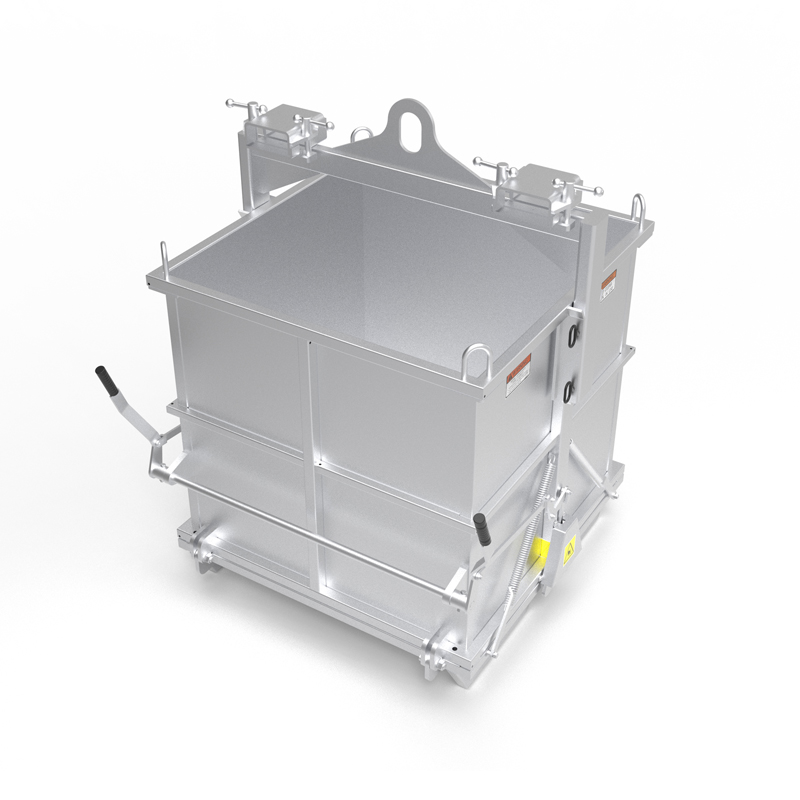

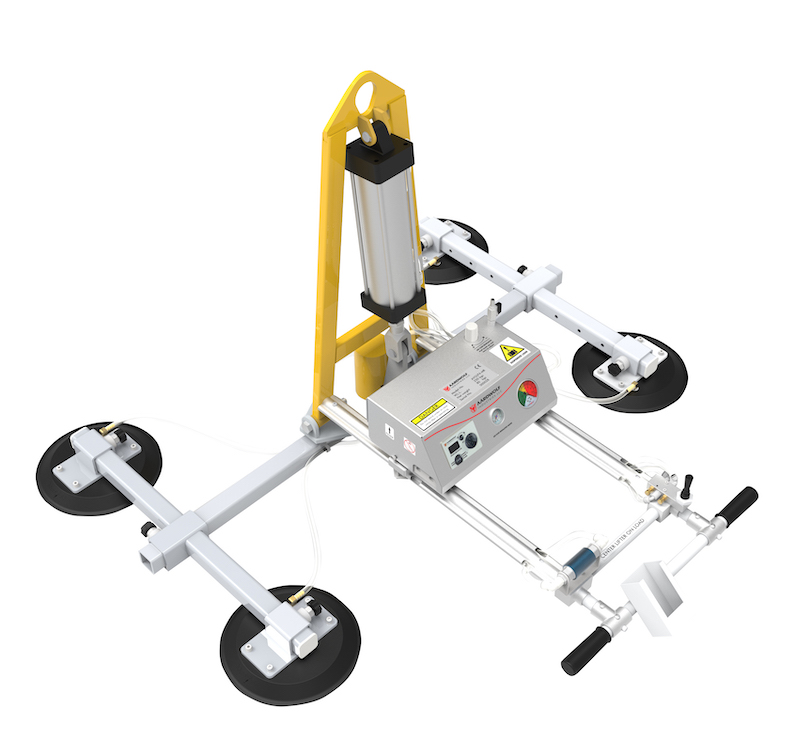

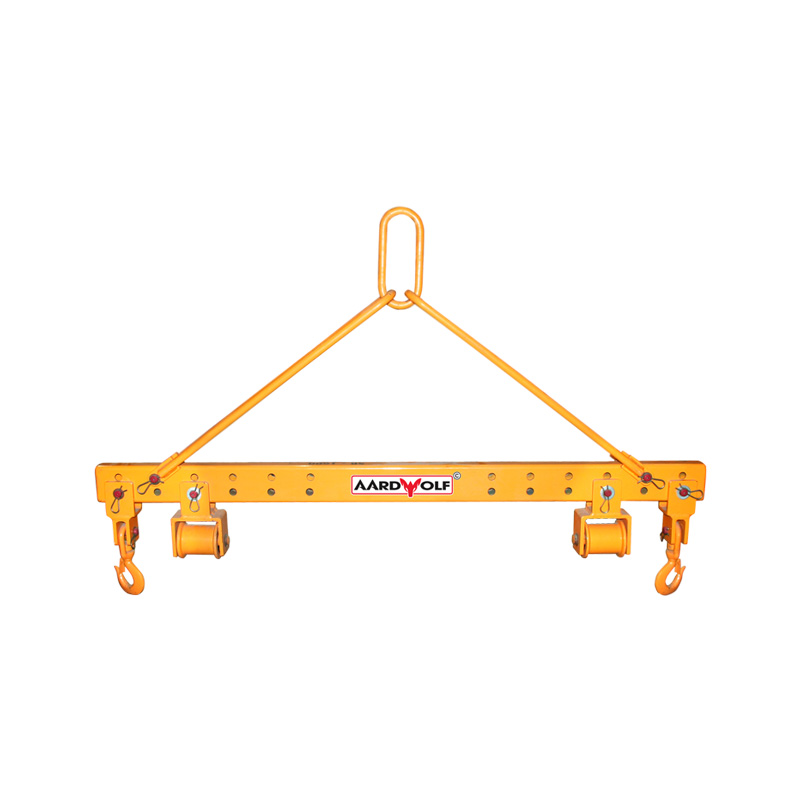

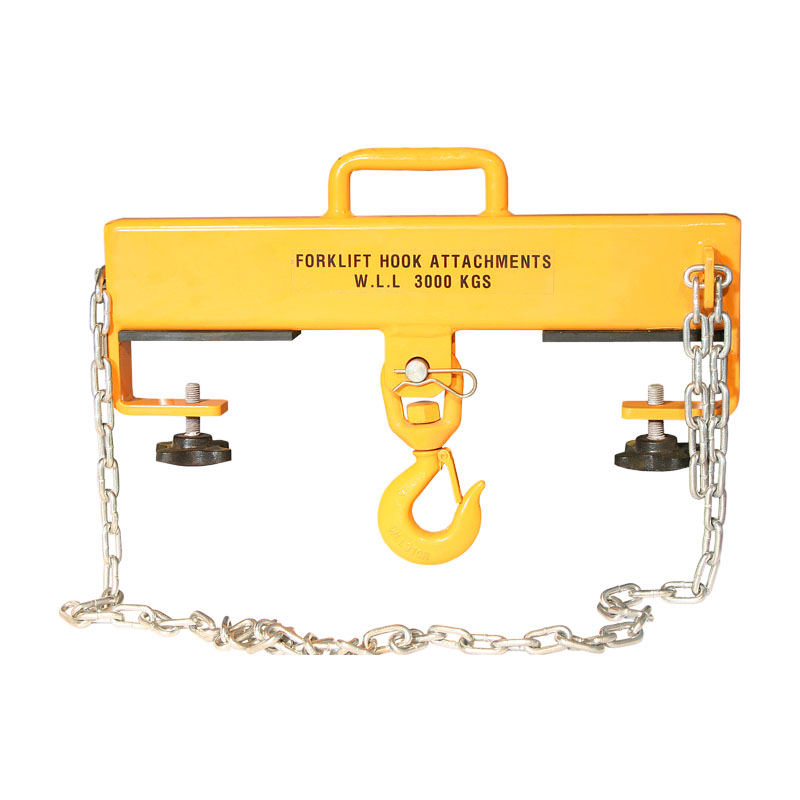

Advanced Lifting Equipment Integration

Aardwolf Work Stations not only optimize material handling processes but also incorporate advanced lifting solutions to further enhance performance.

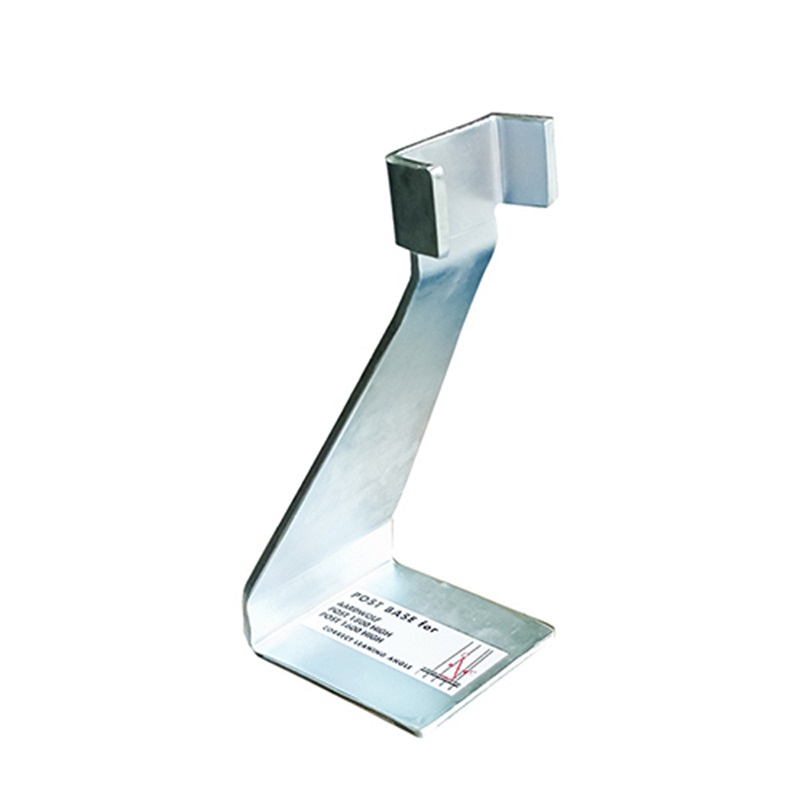

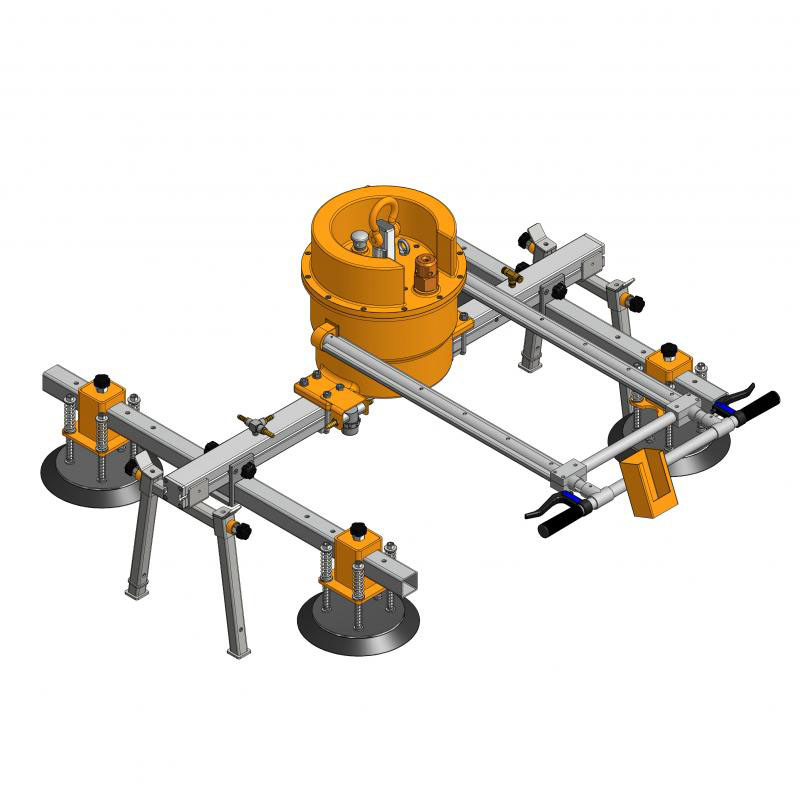

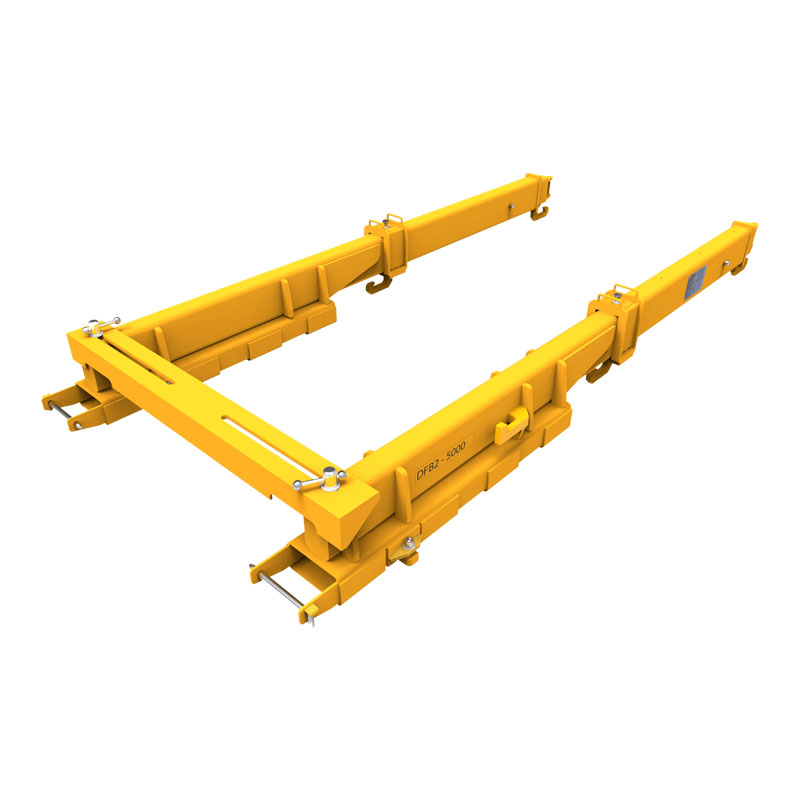

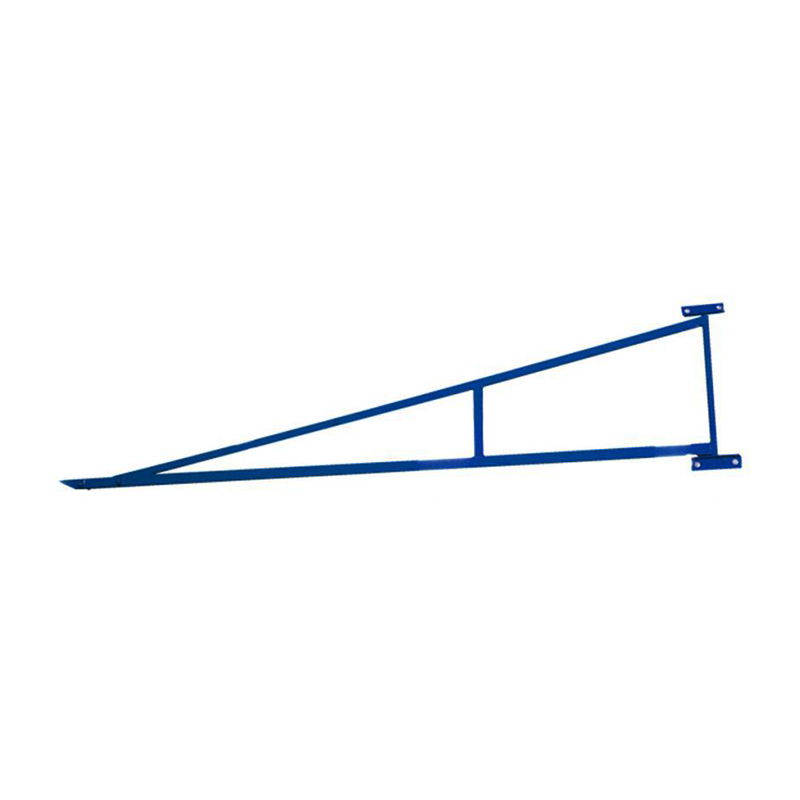

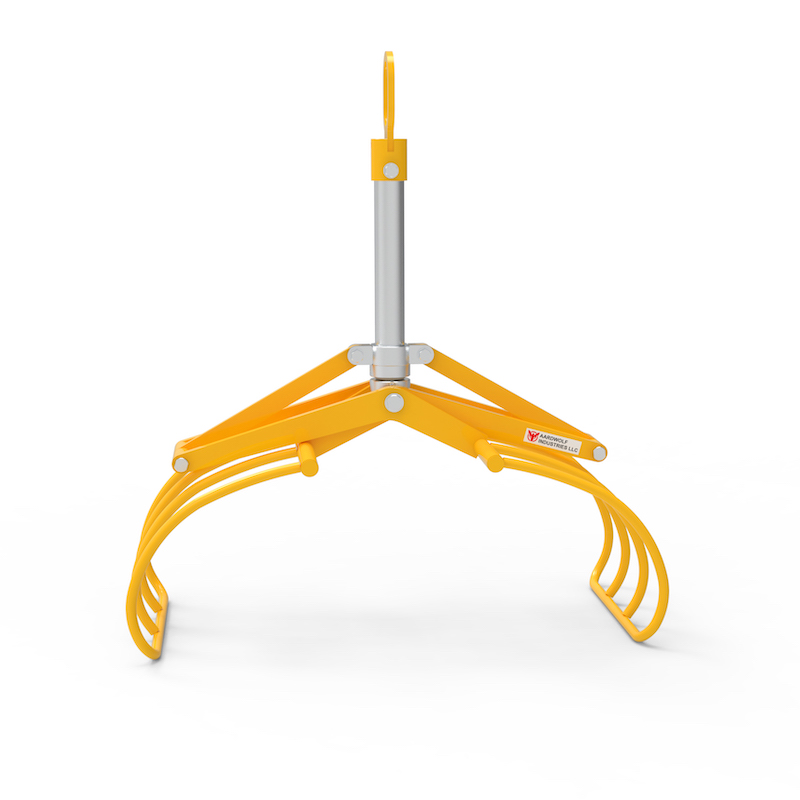

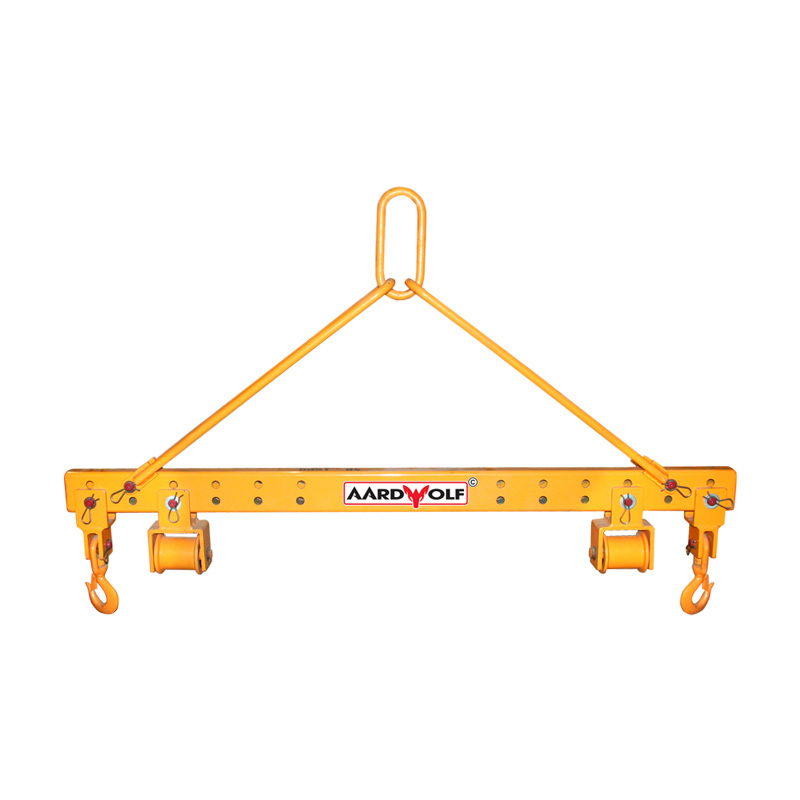

Overhead Swing Arm OSA3000 and OSA4400

-

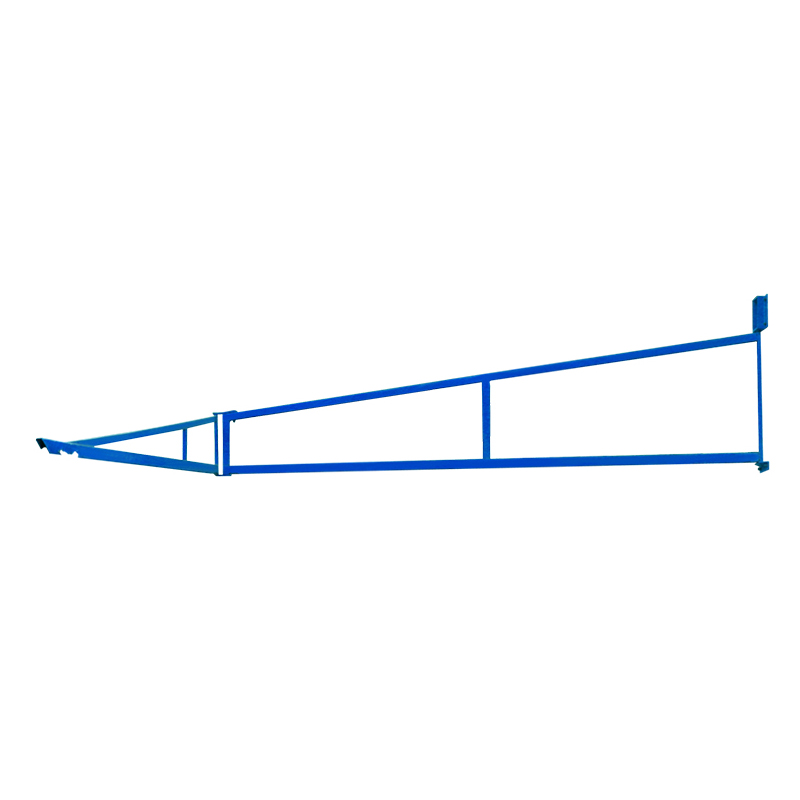

Overhead Swing Arm OSA3000: Ideal for medium-duty applications, this model provides precise control and smooth movement. It is engineered to improve the efficiency of lifting operations, ensuring that materials are moved safely and quickly.

-

Overhead Swing Arm OSA4400: For more demanding applications, the OSA4400 delivers robust performance and stability. It is perfect for heavy-duty operations, offering enhanced safety features and a reliable solution for handling material in high-stress environments.

Why Choose Aardwolf Work Stations?

Aardwolf Work Stations are a game-changer for any business looking to upgrade its material handling equipment. They provide an all-in-one solution that not only streamlines operations but also adapts to various industrial needs. For material handling companies, these work stations mean:

-

Reduced Downtime: Fast and efficient setup leads to uninterrupted operations.

-

Cost Savings: Lower maintenance and operational costs through robust, durable design.

-

Scalability: Easily adjustable to meet the evolving demands of your facility.

-

Enhanced Productivity: Automated and flexible systems speed up the entire material handling process.

Conclusion

In the competitive world of material handling, efficiency, safety, and adaptability are key. Aardwolf Work Stations represent a significant advancement in material-handling equipment, providing a versatile, safe, and efficient solution for modern industries. With integrated lifting systems like the Overhead Swing Arm OSA3000 and OSA4400, these work stations set a new standard in the material handling industry.

Invest in Aardwolf Work Stations today to transform your operations, enhance productivity, and maintain a competitive edge in handling material with state-of-the-art lifting equipment.

Follow us on: